|

Diaphragm Valves

Diaphragm Valves Specification

- Structure

- Diaphragm

- Material

- Cast Iron, Stainless Steel, Plastic, Alloy

- Power

- Manual

- Pressure

- Medium Pressure

- Media

- Water, Gas, Oil, Chemicals

- Working Temperature

- Up to 120C

- Port Size

- 15mm to 300mm

- Surface

- Epoxy Painted, Polished

- Shape

- Straight/Angle

- Application

- Industrial, Water Treatment, Chemical Processing

Diaphragm Valves Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Day

- Delivery Time

- 1 Days

About Diaphragm Valves

Our organization is widely acknowledged as an accredited manufacturer, supplier and exporter of Diaphragm Valves. This valve comes with two or more ports for the passage of fluids. We are always improving our working system so as to better the quality of our products with the help of continues efforts of our research and development team. We employ latest techniques to manufacture these products that further ensure international standards of quality in each product. We use secure machinery to timely deliver these Diaphragm Valves.

Features:

- Durability

- Corrosion resistant

- Sturdy construction

Versatile Design and Durability

These diaphragm valves are available in both straight and angle shapes, offering flexibility for diverse piping layouts in industrial and water treatment facilities. The combination of epoxy painted and polished finishes enhances corrosion resistance, ensuring longevity even in harsh environments. Their robust construction from cast iron, stainless steel, plastic, or alloy provides lasting performance.

Optimal Sealing and Tight Shutoff

Equipped with soft seating, our valves ensure bubble-tight shutoff classified under Leakage Class VIa critical requirement for industries handling hazardous or sensitive media. Whether handling aggressive chemicals or potable water, you are assured of the highest safety standards and process integrity, reducing the risk of leaks or contamination.

Flexible Operation and Mounting

The valves support manual handwheel, pneumatic, and electric actuation to suit varied automation levels. For installation convenience, they can be mounted horizontally or vertically, adapting seamlessly to site constraints. These features make them suitable for new projects or system upgrades, improving process efficiency without extensive modifications.

FAQs of Diaphragm Valves:

Q: What types of fluids are these diaphragm valves suitable for?

A: These diaphragm valves are engineered to handle a wide range of fluids, including acids, alkalis, corrosive media, water, oil, gas, and chemicals. The selection of diaphragm materialEPDM, PTFE, rubber, or nitrileensures compatibility with specific fluid types and operating environments.Q: How do I choose the correct end connection for my application?

A: You should select the end connectionflanged, screwed, or socket weldbased on your systems existing piping, pressure rating, and maintenance requirements. Each connection type provides a secure, reliable fit to suit different industrial installation standards and preferences.Q: When is manual, pneumatic, or electric actuation recommended?

A: Manual handwheel operation is ideal for systems needing cost-effective, occasional adjustments. Pneumatic or electric actuation offers automation and remote control, recommended for frequent or precise valve operation, especially in larger or hard-to-reach systems.Q: Where can these valves be installed in a processing facility?

A: These diaphragm valves are designed for versatile installation; they can be mounted horizontally or vertically. They are suitable for use in water treatment plants, chemical processing units, industrial manufacturing, and any application requiring tight shutoff with aggressive or pure fluids.Q: What benefits does the soft seating and Class VI leakage rating provide?

A: Soft seating ensures bubble-tight shutoff, and achieving Class VI leakage rating means the valve prevents virtually all fluid leakage. This is crucial for process integrity, environmental safety, and compliance with industry regulations, especially when handling hazardous fluids.Q: How is the service life and maintenance profile of these valves?

A: Built for a long cycle life, these valves require minimal maintenance thanks to their durable materials and superior body finish. Simple design facilitates easy replacement of diaphragms and seals, reducing downtime during routine servicing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Valve Category

Swing Check Valves

Minimum Order Quantity : 1 Set

Surface : Other, Red Epoxy Coated

Media : Water

Port Size : 2 to 24 (Inches)

Pressure : High Pressure Bar

Working Temperature : Other, Up to 200C

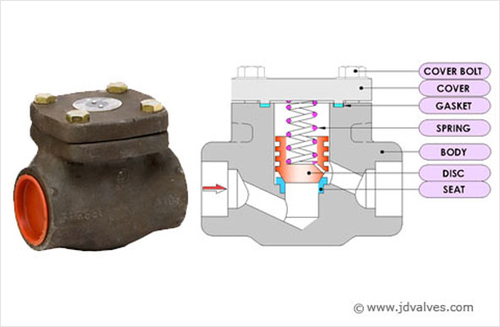

Forged Steel Check Valve

Minimum Order Quantity : 500 Sets

Surface : Other, Anticorrosive Coated

Media : Other, Water, Oil, Steam, Gas

Port Size : 1/2 inch to 2 inches

Pressure : Other, Up to 800 lbs

Working Temperature : Other, 20C to 200C

Slurry Valves

Minimum Order Quantity : 1 Set

Surface : Other, Polished

Media : Other, Slurry

Port Size : 2 Inch

Pressure : High Pressure

Working Temperature : Other, 20C to 200C

Industrial Control Valve

Minimum Order Quantity : 1 Set

Surface : Other, Polished

Media : Other, Water, Air, Gas, Oil

Port Size : 1/2 inch to 8 inch

Pressure : Other, 10 Bar

Working Temperature : Other, 10C to 80C

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry