|

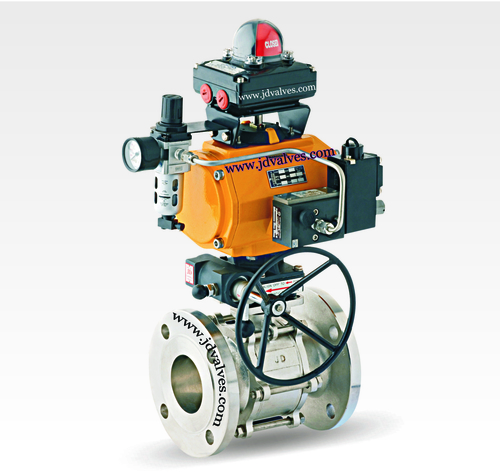

Pneumatic Actuator Operated 3 Way Ball Valve

Pneumatic Actuator Operated 3 Way Ball Valve Specification

- Connection

- Flanged / Screwed / Socket Weld

- Structure

- 3 Way Ball Valve

- Caliber

- Full Bore / Reduced Bore

- Pressure

- Up to PN40 / 600 PSI

- Material

- Stainless Steel / Cast Steel / Brass / PVC / CS (as per application)

- Power

- Pneumatic

- Media

- Water, Air, Gas, Oil, Steam, Chemicals

- Port Size

- 1/2 to 8 (DN15 to DN200)

- Flange

- ANSI, DIN, JIS Standards

- Finish

- Polished / Coated

- Application

- Industrial / Chemical / Petrochemical / Water Treatment / HVAC / Food & Beverage

About Pneumatic Actuator Operated 3 Way Ball Valve

Pneumatic Actuator Operated 3 Way Ball Valve

With through domain expertise of 14 years, we are betrothed to manufacture, export and supply the supreme quality Pneumatic Actuator Operated 3 Way Ball Valve. This valve is ideal for release of liquids, gas, and other substance. Manufactured under the strict vigilance of our diligent professionals by utilizing quality assured raw materials and innovative techniques, this valve is also checked on defined quality parameters. Moreover, this Pneumatic Actuator Operated 3 Way Ball Valve can be purchased by our clients at cost effective prices.

Key Features:

- High durability

- Optimum finish

- Easy to fit

- Rugged design

Design & Testing International Standard:

Butt Weld End: ANSI B 16.25

Face To Face: Mfg. Standard

Flange Drilling: ANSI B 16.5 / BS 10 Table / DIN / IS 6392

Pressure Testing: BS 6755 Part II / API 598 / API 6D

Screwed End: ANSI B 1.20.1(BSP/NPT)

Socket Weld End: ANSI B 16.11

Valve Design: BS 5351 / ANSI B 16.34 / API 6D

Material of Construction:

Body / End Connector Piece:

ASTM A 351 GR. CN 7M (Alloy 20)

Cast Iron to ASTM A 126 Class B IS 210 GR. FG 200 / 220 / 260

Cast Carbon Steel to ASTM A 216 GR. WCB

Ductile Iron to ASTM A 536 Grade 65-45-12

Hast Alloy B / C

Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M

Ball:

Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M

ASTM A 351 GR. CN 7M (Alloy 20)

Hast Alloy B / C

Stem:

AISI 304 (S.S. 304)

AISI 304L (S.S. 304L)

AISI 316 (S.S. 316)

AISI 316L (S.S. 316L)

AISI 410 (S.S. 410 13% Cr. Steel)

Hast Alloy B / C

Alloy 20

Ball Seat / Gland Seal / Stem Seal:

P.T.F.E. Carbon Filled

P.T.F.E. Glass Filled

P.T.F.E. Virgin

Grafoil

High Performance in Complex Applications

This 3-way ball valve ensures reliable diverting or mixing of media, making it suitable for complex flow systems. With full or reduced bore variants and standards-compliant flanged connections, it accommodates various operational requirements across industries such as petrochemical, industrial processing, and water treatment.

Flexible Material and Seal Choices

Choose from stainless steel, cast steel, brass, or PVC bodies and stainless steel or chrome-plated brass balls. Seat and seal options like PTFE, RTFE, PPL, TFM, Viton, or EPDM provide chemical resistance and adaptability to different media and temperatures, ensuring longevity and compatibility in specialized environments.

Pneumatic Actuation for Automation

Equipped with a robust pneumatic actuatoreither double acting or spring returnthis valve simplifies system automation for both on/off and modulating control. The ISO 5211 direct mount and visual/mechanical position indicators facilitate straightforward installation and precise operation.

FAQs of Pneumatic Actuator Operated 3 Way Ball Valve:

Q: How does the pneumatic actuator operated 3 way ball valve function within industrial systems?

A: The valve is designed for diverting or mixing fluid flows, using a 90 rotary pneumatic actuator to change the flow direction. When pressurized air is applied, the actuator rotates the ball, controlling the media path with quick and reliable response, making it suitable for automated system integration.Q: What materials are available for the valve body, and how do I select the appropriate one?

A: Body materials include SS304, SS316, WCB, brass, and PVC. Selection depends on the media type, operating pressure, temperature, and chemical compatibility required for your application. Stainless steel is ideal for corrosive environments, while brass and PVC offer cost-effective options for less aggressive fluids.Q: When should I choose a double acting actuator over a spring return actuator?

A: A double acting actuator is preferable when you require positive air supply for both opening and closing functions, offering precise modulating control. Spring return actuators provide fail-safe operation, returning the valve to its default position upon loss of air, making them suitable for emergency shut-off situations.Q: Where can this valve be used, and what industries benefit from its features?

A: This 3 way ball valve is compatible with water, air, gas, oil, steam, and chemicals, making it popular in the chemical, petrochemical, water treatment, HVAC, and food & beverage sectors. Its robust construction and sealing options suit a wide range of industrial applications.Q: What is the installation process for this valve type?

A: The valve is designed for ISO 5211 direct mount and is available with flanged, screwed, or socket weld end connections according to ANSI, DIN, or JIS standards. Installation typically involves securing to existing piping, connecting the actuator to a pneumatic air supply, and setting up the position indicator.Q: How does the valve ensure reliable tight shut-off and leak prevention?

A: With bubble tight shut-off as standard, the valve uses high-quality PTFE, RTFE, PPL, or TFM seats and elastomeric seals such as Viton or EPDM, effectively preventing leakage even under high pressure and demanding conditions.Q: What are the key operational benefits of using this pneumatically operated 3 way ball valve?

A: Key benefits include automated flow control, long service life, chemical compatibility, flexible installation, and reliable operation even in harsh environments. The bubble-tight shut off and visual or mechanical position indicators provide added safety and operational confidence.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

Automation Series Ball Valve

Minimum Order Quantity : 1 Piece

Structure : Control

Material : Stainless Steel

Finish : Polished

Media : Water

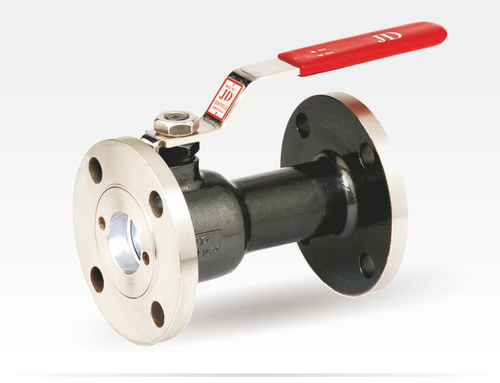

Single Piece Ball Valve

Structure : Other, Single Piece

Material : Stainless Steel

Pressure : Other, Up to 40 Bar

Finish : Mirror/Polished

Media : Other, Water, Oil, Gas, Steam

3 Piece Ball Valves

Minimum Order Quantity : 10 Pieces

Structure : Control

Material : Stainless Steel

Pressure : High Pressure

Finish : Polished

4 Way Ball Valves

Structure : Other, 4 Way Ball Valve

Material : Other, Stainless Steel, Carbon Steel, Brass

Pressure : Other, 1.0 MPa to 6.4 MPa (PN10PN64)

Finish : Polished, Electroplated

Media : Other, Water, Oil, Gas, Steam, Chemical Fluids

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry