|

Globe Control Valves

Globe Control Valves Specification

- Sealing

- PTFE / Metal

- Connection

- Flanged / Screwed / Butt Weld

- Material

- Stainless Steel / Cast Steel

- Power

- Manual / Pneumatic / Electric

- Pressure

- Up to 40 Bar

- Media

- Water, Oil, Gas, Steam

- Port Size

- 1/2 Inch to 12 Inch

- Surface

- Polished

- Shape

- Globe

- Application

- Industrial Fluid Control

- Color

- Silver

- Gland Packing

- PTFE / Graphite

- Trim Material

- Stainless Steel / Alloy Steel

- Operation Type

- Single and Double Seated

- Bonnet Type

- Standard / Extension

- Design Standard

- ASME B16.34

- Flow Characteristic

- Linear / Equal Percentage

- End Connection

- ANSI / DIN Standards

- Actuator Type

- Pneumatic Diaphragm, Electric Motor Operated

- Body Rating

- Class 150 to 900

Globe Control Valves Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Day

- Delivery Time

- 1 Days

About Globe Control Valves

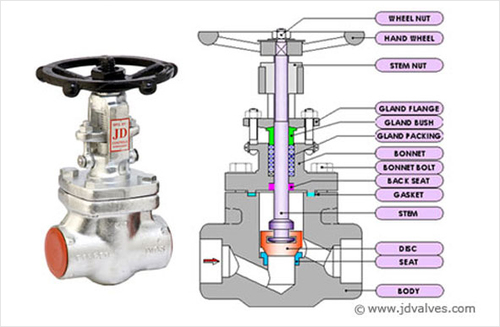

Globe Control Valves

Due to customer orient organization we are highly committed to offer wide assortment of Globe Control Valves. The wide assortment of control valves are highly accurate, safe, reliable and easy to operate. Globe Control Valves are fabricated from the superior quality axenic material procured from the reliable vendors of the market. Our prestigious clients can avail this range of control valves with required modifications. Further we avail these control valves at market leading prices to our prestigious clients.

Globe Control Valves are rising stem, easy to lubricate, outside screw, Bolted Bonnet development and threads are far from the line liquid. These are basically accessible with Plug Type Disk that is intended to provide release tight seating in the long run of in manufactured wear life transverse. The body of valves seat ring is shoulder sort, strung body seat ring that has huge decrease areas, which is for adequate seating. Two pieces of slots are offered on globe control valves body seat ring that is for simple expulsion for servicing at location. Soldered sort seat ring as well as in-built seat ring are additionally obtainable in our valves. Every valve is produced using strong one piece development. The burden shrub of Valve has a long string engagement for exact stem arrangement. Further, the standard scope of our Valve in sizes of approx. 12 (300mm)

Striking Features :

- Bonnet And Body Produced Using Great Casting With Liberal Segments. The Castings Are Exactness Machined For Superior Performance

- Rising Hand And Rising Stem Wheel Development.

- Die Molded Graphite Packaging Rings, Regulated Clearance Among Bonnet, Stem And Gland Bushing For Ensured Less Emissions And Furthermore Appropriate For Higher Temperature.

- Profound Stuffing Box Is Accommodating Snugness And Most Extreme Long Packing Life.

- Swinging Eye Bolts Encourage Simple Access To The Box Of Stuffing.

- Back Seating Highlight Amenities Repacking Of The Box Of Stuffing Alongside The Valve In Completely Vacant Position.

- Seat Ring Twisted Into Valve Body (Replaceable Sort) Or Essential Sort.

- Stellited Disk, Back Seat And Seat Ring Can Likewise Be Provided On Exceptional Demand.

- Higher Size And Higher Pressure Valves Are Given Thrust Bearings As Well As With Gear Drive Systems.

Dimensions (Class 150)

| Size | LF to F | D | E | F | N | O | |

| Inch | DN | ||||||

| 1 | 25 | 127 | 108 | 79.3 | 50.8 | 4 | 15.8 |

| 1 1/2 | 40 | 165.1 | 127 | 98.4 | 73 | 4 | 15.8 |

| 2 | 50 | 203 | 152.4 | 120.6 | 92.1 | 4 | 19 |

| 2 1/2 | 65 | 216 | 177.8 | 139.7 | 104.7 | 4 | 19 |

| 3 | 80 | 241 | 190.5 | 152.4 | 127 | 4 | 19 |

| 4 | 100 | 292 | 228.6 | 190.5 | 157.2 | 8 | 19 |

| 5 | 125 | 256 | 254 | 215.9 | 185.7 | 8 | 22.2 |

| 6 | 150 | 406 | 279 | 214.3 | 215.9 | 8 | 22.2 |

| 8 | 200 | 495 | 343 | 298.4 | 269.9 | 8 | 22.2 |

| 10 | 250 | 623 | 406 | 362 | 323.8 | 12 | 25.4 |

| 12 | 300 | 699 | 483 | 431.8 | 381 | 12 | 25.4 |

Enhanced Performance for Industrial Fluid Control

Engineered to handle demanding environments, these Globe Control Valves provide reliable control for water, oil, gas, and steam applications. With a high body rating from Class 150 to 900 and pressure accommodation up to 40 bar, they are suitable for both light and heavy-duty operations. The selection of trim materials and sealing options ensures compatibility with a range of process conditions.

Flexible Design and Reliable Operation

Our control valves feature multiple actuator typesincluding pneumatic diaphragm and electric motor optionsplus manual operation, for exceptional flexibility in system integration. End connections can be flanged, screwed, or butt weld to meet varied piping requirements, while the standardized design guarantees easy replacement and performance consistency.

FAQs of Globe Control Valves:

Q: How do I determine whether to choose a single or double seated globe valve for my application?

A: Single seated globe control valves are typically chosen for applications requiring tight shutoff, while double seated versions are suitable for handling higher differential pressures with lower actuator force. Consider your process pressure, shutoff requirements, and space constraints when selecting valve type.Q: What benefits do linear and equal percentage flow characteristics offer?

A: Linear flow characteristics deliver a proportional relationship between valve opening and flow rate, ideal for systems needing precise, incremental adjustments. Equal percentage flow provides a more gradual response at lower flows, increasing control accuracy in processes with variable loads or differential pressures.Q: When should I use a standard versus an extension bonnet?

A: A standard bonnet is suitable for typical temperature and pressure conditions, while an extension bonnet is recommended when controlling media at extreme temperatures to protect gland packing and ensure smoother operation.Q: Where can these globe control valves be installed?

A: These valves are designed for industrial settings across various industriessuch as water treatment, power plants, refineries, and chemical processing facilitiesin India and for export, wherever reliable fluid control is needed.Q: What is the process for selecting the correct trim and seal materials?

A: Trim selectionsuch as stainless steel or alloy steeldepends on the corrosiveness and temperature of the media. Sealing options like PTFE or graphite are chosen based on media compatibility, operating conditions, and leakage requirements. Consulting with the manufacturer based on process data ensures optimal material choice.Q: How does the type of actuator impact valve usage and benefits?

A: Pneumatic diaphragm actuators offer rapid, reliable adjustments and are suitable for automated processes. Electric motors are ideal where electrical integration or remote control is needed. Manual operation is available for simpler systems or backup in case of actuation failure.Q: What are the main advantages of meeting ASME B16.34 design standards?

A: Adherence to ASME B16.34 ensures that the globe control valves meet recognized safety, durability, and pressure integrity standards, which is critical for compliance in regulated industries and for securing long-term, trouble-free operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Globe Valves Category

Forged Steel Globe Valve

Minimum Order Quantity : 1 Set

Shape : Round Body

Application : Other, Industrial Pipelines, Refineries, Power Plants

Connection : Other, Screwed (BSP/NPT), Socket Weld, Flanged

Material : Other , Forged Carbon Steel (A105)

Surface : Other , Rust Proof Coated Finish

Pneumatic Control Valve

Minimum Order Quantity : 1 Set

Shape : Round

Application : Other, Industrial Automation, Fluid Control

Connection : Other, Flanged/Threaded

Material : Stainless Steel

Surface : Other , Polished

Industrial Globe Valves

Minimum Order Quantity : 1 Set

Shape : Round Body

Application : Other, Industrial Pipelines, Steam Plants, Oil & Gas Industry

Connection : Other, Flanged Ends, Screwed Ends, Butt Welded

Material : Other , Cast Iron, Cast Steel, Stainless Steel

Surface : Other , Polished / Painted

Smart Type Control Valve

Minimum Order Quantity : 1 Set

Shape : Cylindrical

Application : Other, Industrial Automation

Connection : Other, Flanged / Threaded

Material : Stainless Steel

Surface : Other , Polished

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry