|

Pneumatic Control Valve

Pneumatic Control Valve Specification

- Connection

- Flanged/Threaded

- Sealing

- PTFE

- Material

- Stainless Steel

- Power

- Pneumatic

- Pressure

- Up to 16 Bar

- Media

- Air, Water, Gas, Oil

- Port Size

- 1/2 Inch to 4 Inch

- Surface

- Polished

- Shape

- Round

- Application

- Industrial Automation, Fluid Control

- Color

- Silver & Black

Pneumatic Control Valve Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Day

- Delivery Time

- 1 Days

About Pneumatic Control Valve

Pneumatic Control Valve

We have 12 years of experience in the sphere of manufacturing, exporting and supplying of Pneumatic Control Valve. Made of quality material this control valve is highly efficient, leak resistant and corrosion resistant. Pneumatic Control Valve is manufactured using optimum quality material which ensures durability and reliability to clients. Furthermore the wide assortment of control valve can be availed with the specifications demanded by our esteemed clients. We offer control valve at very affordable rates.

Precision & Versatility for Industrial Control

Our pneumatic control valves are engineered for customizable control in demanding environments. Available with single or double acting actuators, they offer linear or equal percentage flow characteristics, making them ideal for various process applications. These valves come in both 2-way and 3-way types with ANSI/BS/DIN flanged or threaded ends, and support a range of media from air to oil. They ensure reliable, bubble-tight sealing and efficient operation in automation systems.

Robust Stainless Steel Construction

Crafted from high-grade stainless steel (SS 304/316), these valves offer superior durability and resistance to corrosion. The stems and body components are suitable for aggressive media, supported by EPDM or NBR diaphragms and PTFE sealing for enhanced longevity and performance under pressure. The polished, silver and black design ensures robust service in tough industrial settings.

FAQs of Pneumatic Control Valve:

Q: How does a single acting pneumatic actuator differ from a double acting actuator in these control valves?

A: A single acting pneumatic actuator uses air pressure to move the valve in one direction and relies on a spring for the return movement. In contrast, a double acting actuator utilizes air pressure for both opening and closing, offering greater control and force, which is beneficial for more demanding applications or faster operation.Q: What are the benefits of using soft seated versus metal seated control valves?

A: Soft seated valves, typically lined with PTFE or similar material, provide superior bubble-tight leakage (Class VI), making them ideal for applications requiring zero leakage. Metal seated valves, meanwhile, endure higher temperatures and abrasive conditions, making them suitable for harsh industrial media.Q: When is it recommended to choose a 2-way versus a 3-way control valve configuration?

A: A 2-way control valve is best for simple on/off or flow modulation operations in a single pipeline. A 3-way valve, however, is used when mixing or diverting flows is required, such as in complex process systems where two streams need to be combined or separated.Q: Where are these pneumatic control valves commonly used?

A: These valves are widely applied in industrial automation, fluid handling systems, and process control industries across air, water, oil, and gas applications. Their versatility makes them suitable for manufacturing plants, chemical processing, water treatment facilities, and energy sectors.Q: What is the standard procedure for pressure testing these control valves?

A: Each valve undergoes a body pressure test at 1.5 times the rated pressure to ensure structural integrity and leak prevention. This process ensures safe performance and compliance with international standards before shipping.Q: How does the inclusion of a position indicator enhance valve operation?

A: A position indicator provides visual feedback on the valves open or closed state, enabling operators to quickly verify system status, improve safety, and simplify maintenance in automated environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Globe Valves Category

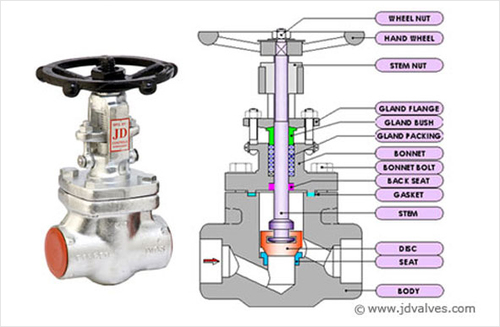

Forged Steel Globe Valve

Minimum Order Quantity : 1 Set

Connection : Other, Screwed (BSP/NPT), Socket Weld, Flanged

Power : Manual

Port Size : 1/2 to 2 (DN15 to DN50)

Sealing : Metal to Metal/Soft Seat

Color : Black

Globe Control Valves

Minimum Order Quantity : 1 Set

Connection : Other, Flanged / Screwed / Butt Weld

Power : Other , Manual / Pneumatic / Electric

Port Size : 1/2 Inch to 12 Inch

Sealing : PTFE / Metal

Color : Silver

Industrial Globe Valves

Minimum Order Quantity : 1 Set

Connection : Other, Flanged Ends, Screwed Ends, Butt Welded

Power : Manual

Port Size : 15 mm to 300 mm

Sealing : Metal to Metal, PTFE, Graphite

Color : Blue / Silver

Smart Type Control Valve

Minimum Order Quantity : 1 Set

Connection : Other, Flanged / Threaded

Power : Other , 24V DC / 220V AC

Port Size : 1/2 to 8 Inch

Sealing : PTFE

Color : Silver and Blue

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry