|

3 Way Gear Operated Ball Valve

3 Way Gear Operated Ball Valve Specification

- Connection

- Flanged End

- Structure

- 3 Way Ball Valve

- Pressure

- 150# / 300# / 600#

- Channels

- L Port / T Port

- Caliber

- Full Bore / Reduced Bore

- Material

- Stainless Steel / Carbon Steel / Alloy Steel

- Power

- Manual Gear Operated

- Media

- Water, Gas, Oil, Steam, Chemicals

- Port Size

- 1/2 to 12 (DN15 to DN300)

- Flange

- ANSI, DIN, JIS Standard

- Finish

- Shot Blasted, Painted, or As Required

- Application

- Industrial Pipelines, Chemical Processing, Oil & Gas, Water Treatment

- Automation

- Actuator Mounting Possible

- Mounting Pad

- ISO 5211

- Operation

- Quarter Turn Gearbox

- Fire Safe

- Available as Option

- Anti-static Device

- Provided

- Design Standard

- API 6D / ASME B16.34 / BS

- End Connection

- Butt Weld Available on Request

- Seat Material

- PTFE / RPTFE / CFT / Metal Seat

- Blow-out Proof Stem

- Standard Feature

- Body Test Pressure

- 1.5 times working pressure

- Weight

- Varies as per Size and Material Specification

- Working Pressure Range

- Up to 40 Bar

- End Flange Drilling

- ASME B16.5, DIN, JIS

- Leakage Class

- Class VI / Bubble Tight

- Face to Face Dimension

- ASME B16.10

About 3 Way Gear Operated Ball Valve

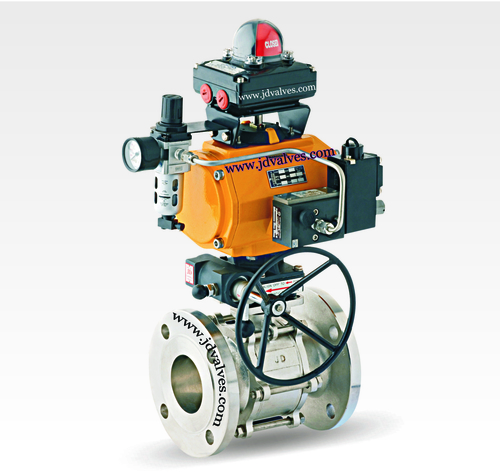

3 Way Gear Operated Ball Valve

With the assistance of our team of professionals, we are engaged in providing an assorted range of 3 Way Gear Operated Ball Valve that is available in diverse finishes and sizes. This valve is used for controlling the flow of liquid in industrial sector. Provide double block function and tight shutoff, the offered valve is manufactured using supreme quality raw material and latest machines. This 3 Way Gear Operated Ball Valve is offered at market leading prices.

Key Features:

- Durable finish standards

- High tensile strength

- Dimensional accuracy

- Easy to operate

Superior Design and Versatility

This 3 Way Ball Valve features flexible port configurationsL or T portsand a choice of full or reduced bore calibers. Available in stainless steel, carbon steel, and alloy steel, it accommodates various process demands. End connections include flanged and optional butt weld for installation flexibility. The valve is suitable for water, gas, oil, steam, and chemical applications across industrial, oil & gas, and water treatment sectors.

Operational Reliability and Safety

With a quarter-turn gear-operated mechanism, the valve delivers smooth manual operation and can be automated via actuator mounting (ISO 5211). It incorporates anti-static devices for hazardous media, a blow-out proof stem, and optional fire-safe design for enhanced operational safety under critical conditions. Face-to-face and flange dimensions comply with ASME/DIN/JIS standards for direct replacement or integration.

FAQs of 3 Way Gear Operated Ball Valve:

Q: How does the quarter-turn gearbox mechanism operate the 3 Way Ball Valve?

A: The quarter-turn gearbox converts manual rotation into a 90-degree movement, enabling swift and controlled selection of flow paths (L or T port). This provides simple, reliable handling even at higher pressures or for larger valve sizes.Q: What are the benefits of selecting different seat materials like PTFE, RPTFE, CFT, or metal?

A: Each seat material offers specific advantages: PTFE and RPTFE provide excellent chemical resistance and low friction, CFT offers elevated temperature capability, and metal seats handle abrasive media and higher temperatures. Selection depends on the media and process conditions.Q: When is a fire-safe valve necessary, and is it available for this product?

A: A fire-safe valve is crucial when operating in environments at risk of fire or extreme heat, ensuring containment even if the seat material degrades. This valve offers a fire-safe design as an optional feature for such scenarios.Q: Where can this 3 Way Ball Valve be installed?

A: The valve is designed for use in industrial pipelines, chemical processing plants, oil & gas facilities, and water treatment systems. Its standards-compliant construction makes it suitable for new installations or as a direct replacement in existing systems.Q: What is the process for automation and actuator mounting?

A: This valve comes with an ISO 5211 mounting pad, making it compatible with standard actuators. Automation can be achieved by attaching electric or pneumatic actuators, allowing for remote or sequenced control.Q: How does the anti-static device provide additional safety?

A: The anti-static device ensures electrical continuity between the ball, stem, and body, preventing static charge buildup. This is especially important for flammable or volatile media, reducing the risk of ignition.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

Pneumatic Ball Valve

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Pressure : Other, PN16 / PN25 / 150PSI

Finish : Polished

Structure : Other, Ball Valve

Caliber : Standard

Fire Safe Ball Valve

Material : Other, Stainless Steel / Carbon Steel

Pressure : Other, Class 150 to Class 800

Finish : Polished / Coated

Structure : Other, Ball Valve

Caliber : Full Bore

Jacketed Ball Valves

Material : Other, Stainless Steel, Carbon Steel, Alloy Steel

Pressure : Other, Class 150 to 900

Finish : Polished or Painted

Caliber : Standard & Customized

3 Piece Ball Valves

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Pressure : High Pressure

Finish : Polished

Structure : Control

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry