|

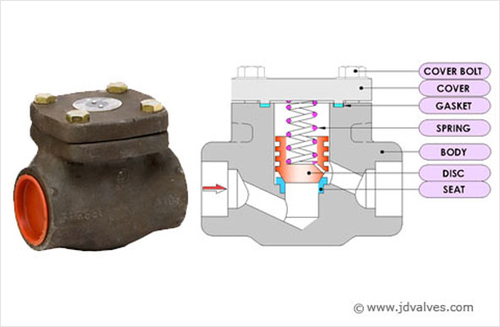

Forged Steel Check Valve

Forged Steel Check Valve Specification

- Structure

- Swing Type / Lift Type

- Material

- Forged Steel

- Power

- Manual

- Pressure

- Up to 800 lbs

- Media

- Water, Oil, Steam, Gas

- Working Temperature

- -20C to 200C

- Port Size

- 1/2 inch to 2 inches

- Surface

- Anti-corrosive Coated

- Shape

- Y-pattern / T-pattern

- Application

- Oil, Gas, Petrochemical Industries

- Design Standard

- API 602 / ASME B16.34

- Bonnet Type

- Bolted Bonnet / Welded Bonnet

- End Connection

- Socket Weld / Screwed (BSP/NPT/FNPT)

- Size Range

- 15 mm to 50 mm

- Body Material Grade

- A105 / F304 / F316

- Suitable Fluids

- Corrosive & Non-corrosive Media

- Leak Tightness

- Zero Leakage Seat

- Face to Face Dimension

- As per ANSI B16.10

- Testing Standard

- API 598

- Body Test Pressure

- 20.0 MPa

- Gasket Material

- Spiral Wound Stainless Steel with Graphite

- Seat Test Pressure

- 13.8 MPa

- Operation

- Non-return Valve (Check)

Forged Steel Check Valve Trade Information

- Minimum Order Quantity

- 500 Sets

- Supply Ability

- 1000 Sets Per Day

- Delivery Time

- 1 Days

About Forged Steel Check Valve

We have uniquely positioned ourselves as a dependable firm, engaged in manufacturing and supplying Forged Steel Check Valve. The valve has body guided cylinder guaranteeing exact reverse to seat ring in order to accomplish spill tightness. We manufacture this valve under the firm guidance of expert supervisors suing high quality cast iron. It is used for throttling flow control in chemical, petrochemical and food industry. The flow pattern through a gate valve involves changes in direction, resulting in greater resistance to flow, causing high pressure drop. We offer Forged Steel Check Valve at affordable prices.

Features:

- Resistant to corrosion

- Rugged construction

- Maintenance free

Superior Sealing and Leak Prevention

With a spiral wound stainless steel gasket combined with graphite, our check valve ensures tight sealing and zero leakage seat integrity. Rigorous body and seat pressure tests, in accordance with API 598, guarantee reliable operation even under high pressure, making it well-suited for demanding processes in the oil, gas, and petrochemical industries.

Versatile Compatibility and End Connections

Engineered for flexibility, this forged steel check valve is available in socket weld or screwed (BSP/NPT/FNPT) end connections. With a size range from 15 mm to 50 mm and port sizes from 1/2 inch to 2 inches, it integrates seamlessly into new or existing piping setups, ensuring compatibility for numerous industrial fluid applications.

FAQs of Forged Steel Check Valve:

Q: How does the Forged Steel Check Valve ensure zero leakage in high-pressure environments?

A: The valve uses a spiral wound stainless steel gasket with graphite and undergoes rigorous seat and body pressure testing (API 598), resulting in a zero leakage seat. Its bolted or welded bonnet options enhance sealing integrity, making it highly reliable for high-pressure systems.Q: What materials are available for the valve body and which media can the valve handle?

A: Valve body materials include A105, F304, and F316 forged steel, suitable for use with both corrosive and non-corrosive fluids such as water, oil, gas, and steam. This versatility supports applications in oil, gas, and petrochemical industries.Q: When should a swing type or lift type structure be selected for the check valve?

A: A swing type is ideal for applications with horizontal flow and minimal pressure drop, while lift type is best used for vertical or high-velocity flows. The selection depends on your piping layout and process requirements.Q: Where are Forged Steel Check Valves typically installed?

A: These valves are commonly installed in pipelines where backflow prevention is critical, especially in oil refineries, gas processing units, and petrochemical plants. Theyre suitable for both new projects and retrofitting in existing systems with compatible connection types.Q: What is the process for ensuring the valve meets required standards?

A: Each valve is manufactured to conform to API 602 and ASME B16.34 design standards, followed by comprehensive testing according to API 598. Pressure and leak tightness checks ensure every product meets industrial safety and performance requirements.Q: How does the anti-corrosive coating benefit the valves lifespan and performance?

A: The specialized anti-corrosive surface treatment protects the valve against harsh process environments, reducing wear and extending operating life, even when handling aggressive or abrasive fluids.Q: Can this check valve be used at both high and low temperatures?

A: Yes, the valve is designed for a wide temperature range from -20C to 200C, maintaining its sealing and structural integrity throughout, making it suitable for various process conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Valve Category

Swing Check Valves

Minimum Order Quantity : 1 Set

Port Size : 2 to 24 (Inches)

Material : Other, Mild Steel

Structure : Other, Single Door

Power : Manual

Media : Water

Diaphragm Valves

Minimum Order Quantity : 1 Set

Port Size : 15mm to 300mm

Material : Other, Cast Iron, Stainless Steel, Plastic, Alloy

Structure : Diaphragm

Power : Manual

Media : Other, Water, Gas, Oil, Chemicals

Slurry Valves

Minimum Order Quantity : 1 Set

Port Size : 2 Inch

Material : Stainless Steel

Structure : Gate

Power : Manual

Media : Other, Slurry

Industrial Control Valve

Minimum Order Quantity : 1 Set

Port Size : 1/2 inch to 8 inch

Material : Other, Cast Steel

Structure : Other, Globe Type

Power : Pneumatic

Media : Other, Water, Air, Gas, Oil

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry