|

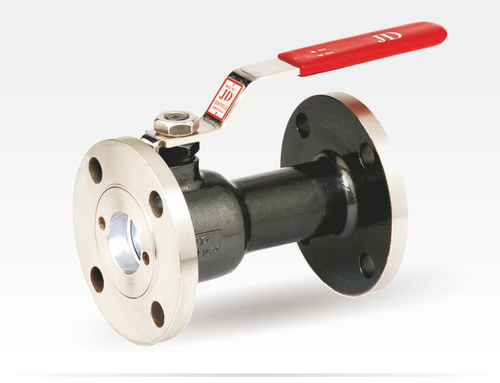

Forged Steel High Pressure Ball Valve

Forged Steel High Pressure Ball Valve Specification

- Structure

- Ball Valve

- Connection

- Screwed / Socket Weld / Flanged

- Pressure

- Up to 6000 PSI (420 bar)

- Caliber

- High Precision Caliber

- Channels

- Two-way

- Material

- Forged Steel

- Power

- Manual

- Media

- Water, Oil, Gas, Steam

- Temperature of Media

- High Temperature

- Port Size

- 1/2 inch to 2 inch (varies by model)

- Flange

- ANSI B16.5, DIN, JIS Standard Available

- Finish

- Anti-Corrosion Coated

- Application

- Industrial, Petrochemical, Power Plants, High Pressure Systems

- Fire Safe Design

- Optional

- Seat Test Pressure

- 1.1 x Rated Pressure

- Seat Material

- PTFE / R-PTFE / Metal

- Size Range

- DN15 ~ DN50

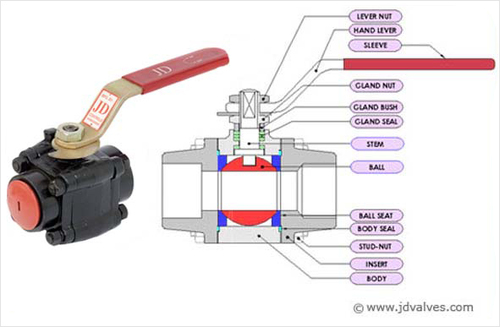

- Stem Material

- Stainless Steel

- Ball Material

- Stainless Steel / Chrome Plated Steel

- Body Material

- ASTM A105 / A182 F304 / F316 Forged Steel

- Body Test Pressure

- 1.5 x Rated Pressure

- Leakage Class

- Bubble Tight, Class VI

- End Connection

- Screwed (BSP/NPT), Socket Weld, Flanged

- Design Standard

- API 6D / BS 5351 / ASME B16.34

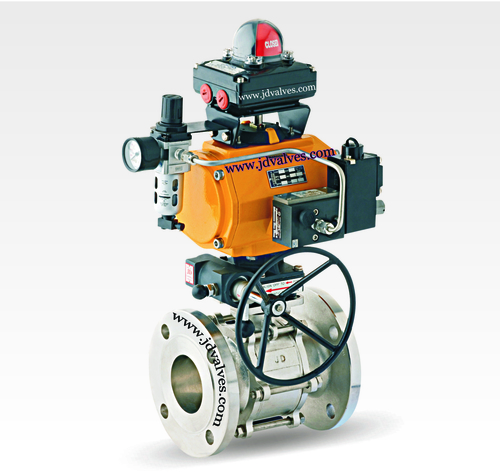

- Operation Type

- Quarter Turn

- Surface Treatment

- Anti-rust Oil Coating

- Blowout Proof Stem

- Yes

- Operating Temperature Range

- -29°C to 200°C (Depending on Material)

About Forged Steel High Pressure Ball Valve

Our strength lies in our proficient team of engineers and dexterous workforce, helps us in manufacturing and supplying Forged Steel High Pressure Ball Valve. This valve is known for zero leakage, tight shut-off and low torque with easy smooth operation at high temperature. At our sophisticated production unit, we manufacture this valve using high quality mild steel. It is supplied with manual hand lever or gear unit operated, depending on valves size. Available in different sizes and specifications, this Forged Steel High Pressure Ball Valve is used in tanks, pipelines and vessels.

Features:

- Positive shut off

- Low pressure drop

- Resistant to rust

Further Details:

These Ball Valves are available Three Piece outline ranging from 1/2 to 2 to meet different non critical and critical uses as well as pressure grading of approximately to 800 grade in reduce (regular) bore plan.

Salient Features :

- High Performance Ball Valve

- Longer Life

- Positive Shut off

- Quick in Action

- No Lubrication

- Compact Design

- Low Pressure Drop

- Simplicity

WIDE RANGE OF BODY SEAT, SEAL & PACKING

J D Ball Valves are also available with different type of Seat, Seal & Packing material such as P.T.F.E. (Virgin) / Glass Filled P.T.F.E. / Carbon Filled P.T.F.E. / Graphite (Grafoil) / PEEK to suit special requirement of client.

Design & Testing International Standard:

| Valve Design | BS 5351 / ANSI B 16.34 |

| Pressure Testing | BS 6755 Part II / API 598 |

| Face To Face | ANSI B 16.10 |

| Butt Weld End | ANSI B 16.25 |

| Socket Weld End | ANSI B 16.11 |

| Screwed End | ANSI B 1.20.1(BSP/NPT) |

Engineered for Efficiency and Safety

This ball valve delivers bubble-tight, Class VI leakage protection, guaranteeing exceptional sealing in high-pressure operations. Its robust forged steel body and anti-corrosion coating resist harsh environments, while the blowout-proof stem design safeguards against stem expulsion under pressure. Available in several sizes (DN15 to DN50), it supports flexible installation due to multiple end connections and complies with international standards for critical industrial usage.

Customizable for Diverse Applications

Suitable for water, oil, gas, and steam, this valve can be tailored with different ball and seat materials to meet specific media and temperature requirements. The quarter-turn manual operation enables precise flow control, while optional fire-safe features enhance reliability and safety in hazardous conditions. Its two-way channel and high-precision caliber ensure consistent performance across a range of industrial systems.

FAQs of Forged Steel High Pressure Ball Valve:

Q: How is the forged steel high pressure ball valve typically used in industrial systems?

A: This valve is used to regulate or shut off the flow of water, oil, gas, or steam in high-pressure environments such as petrochemical plants, power generation facilities, and general manufacturing. Its bubble-tight seal and robust construction make it ideal for operations requiring leak-free performance and durability.Q: What materials are available for the ball, seats, and stem of this valve?

A: The ball can be supplied in stainless steel or chrome-plated steel. Seats are available in PTFE, reinforced PTFE (R-PTFE), or metal, while the stem is made from stainless steel. These options allow customization for different media types and temperature ranges.Q: When should the fire-safe design option be considered for this valve?

A: The fire-safe design should be selected when the valve is installed in environments where there is a risk of fire or exposure to hazardous substances. It provides an additional layer of protection by ensuring the valve maintains its integrity and sealing capability in high-temperature fire conditions.Q: Where can this ball valve be installed and what connection types are supported?

A: This valve can be installed in a range of systems, including pipelines and equipment in industrial, petrochemical, and power plant settings. Supported connections include screwed (BSP/NPT), socket weld, and flanged ends, with flange standards ANSI B16.5, DIN, and JIS available to fit various regional requirements.Q: What is the testing process to ensure valve integrity and performance?

A: Each valve undergoes a stringent testing regimen, including body test pressure at 1.5 times rated pressure and seat test pressure at 1.1 times rated pressure. These tests confirm the valves capability to withstand high pressures and deliver bubble-tight, Class VI leakage protection.Q: How does the quarter-turn operation benefit system control?

A: The quarter-turn mechanism allows for rapid and precise opening or closing of the valve, facilitating quick shut-off or regulation of flow with minimal operator effort. This contributes to efficient process control and reduces downtime during maintenance or emergencies.Q: What are the advantages of using a forged steel ball valve in high pressure applications?

A: Forged steel construction provides superior strength, resistance to cracking, and longevity under extreme pressures. Combined with anti-rust and anti-corrosion coatings, these valves offer reliable performance and low maintenance costs in harsh or corrosive industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

Single Piece Ball Valve

Material : Stainless Steel

Pressure : Other, Up to 40 Bar

Finish : Mirror/Polished

Structure : Other, Single Piece

3 Way Gear Operated Ball Valve

Material : Other, Stainless Steel / Carbon Steel / Alloy Steel

Pressure : Other, 150# / 300# / 600#

Finish : Shot Blasted, Painted, or As Required

Structure : Other, 3 Way Ball Valve

3 Piece Ball Valves

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Pressure : High Pressure

Finish : Polished

Structure : Control

Color : Black

3 Way Ball Valve Screwed End

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Pressure : High Pressure

Finish : Polished

Color : Silver

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry