|

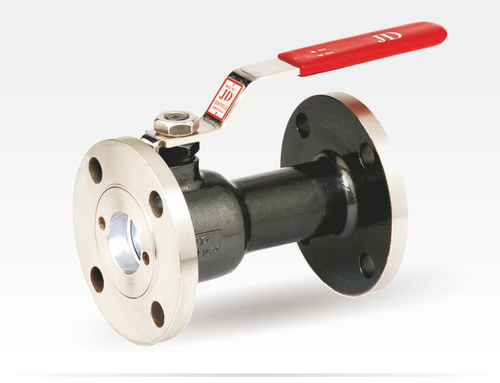

Pneumatic Ball Valve

Pneumatic Ball Valve Specification

- Connection

- Flanged

- Structure

- Ball Valve

- Channels

- 2 Way

- Caliber

- Standard

- Pressure

- PN16 / PN25 / 150PSI

- Material

- Stainless Steel

- Power

- Pneumatic

- Media

- Water, Air, Oil, Gas

- Port Size

- 1/2 inch to 6 inch

- Flange

- ANSI/DIN/JIS Standard

- Finish

- Polished

- Application

- Industrial, Chemical, Water Treatment, Oil & Gas

- End Connection

- Flanged as per ANSI B16.5/DIN/JIS

- Actuator Type

- Double Acting and Spring Return

- Body Style

- 2 Piece / 3 Piece

- Seal Material

- PTFE

- Working Pressure

- up to 25 Bar

- Leakage Class

- Class VI (Bubble Tight)

- Operation

- On/Off

- Mounting

- ISO 5211 Direct Mount

Pneumatic Ball Valve Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Letter of Credit (L/C), Cash Against Delivery (CAD), Delivery Point (DP), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Sets Per Week

- Delivery Time

- 2 Days

- Main Export Market(s)

- Western Europe, Central America, Eastern Europe, North America

- Main Domestic Market

- All India

About Pneumatic Ball Valve

Pneumatic Ball Valve

Committed to total customer satisfaction we manufacture, supply and export quality reliable range of Pneumatic Ball Valve. Being light in weight, compact size and durable, ball valve is extensively used in the various sectors such as fertilizer, pharmaceutical and agrochemical industries. Pneumatic Ball Valve is manufactured using premium quality of materials. Furthermore, the offered ball valve is rendered in compliance with the various demands of our prestigious clients. These valves are available in market at reasonable prices.

Versatile Applications Across Industries

This pneumatic ball valve adapts to a range of industrial environmentschemical processing, water treatment, oil & gas, and more. Its robust stainless steel construction withstands harsh conditions, while the PTFE seat ensures leak-free performance with various media including water, oil, air, and gas.

Reliable Performance and Easy Maintenance

With bubble-tight (Class VI) leakage, and a polished finish for resistance to corrosion and wear, this valve is designed for reliability. The 2-piece or 3-piece structures facilitate straightforward maintenance and replacement, maximizing operational uptime and efficiency.

Global Standards and Direct Mount Design

The valves flanged ends conform to ISO, ANSI, DIN, and JIS standards, supporting global export requirements. The ISO 5211 direct mount allows for quick and secure actuator installation, streamlining the assembly and ensuring compatibility with leading actuator systems.

FAQs of Pneumatic Ball Valve:

Q: How is a pneumatic ball valve with a PTFE seal installed in an industrial system?

A: The valve is mounted directly onto your systems pipework using the flanged ends, which conform to ANSI, DIN, or JIS standards, and is secured according to ISO 5211 mounts. Pneumatic supply lines are then connected to the actuatoreither double acting or spring return, depending on your automation needs.Q: What benefits does the PTFE seal provide in this ball valve?

A: PTFE seals deliver excellent chemical resistance and durability, ensuring a tight, bubble-free shutoff (Class VI leakage) even with aggressive media. This results in lower maintenance requirements and maximized operational reliability for your facility.Q: When should I choose a double acting versus spring return actuator for this valve?

A: Choose a double acting actuator when you need powered opening and closing in both directions, ideal for automated processes requiring precise control. Opt for a spring return actuator when you need the valve to automatically return to a fail-safe position, enhancing safety during power or air failures.Q: Where can this pneumatic ball valve be used effectively?

A: This valve is designed for diverse industrial applicationschemical plants, water treatment facilities, oil & gas installations, and any process requiring robust on/off flow control under pressures up to 25 Bar with standardized flanged connections.Q: What is the process for maintenance or replacement of this ball valve?

A: Thanks to the 2-piece or 3-piece body styles, maintenance is straightforward: simply isolate the valve, depressurize the line, unfasten the valve from flanges, and perform needed seal or component replacements. This design minimizes downtime in industrial settings.Q: How does the ISO 5211 direct mount enhance valve operation?

A: The ISO 5211 direct mount standard allows actuators to be attached easily and precisely to the valve, reducing installation time and ensuring correct positioning for optimal performance, with less risk of alignment error compared to custom mountings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

Jacketed 3 Way Ball Valve

Material : Stainless Steel

Media : Other, Water, Oil, Gas, Steam, Chemicals

Connection : Flanged

Power : Manual

Pressure : Other, PN16 to PN40

Caliber : Full Bore

Mounting Pad Ball Valves

Material : Other, Stainless Steel / Carbon Steel / Cast Iron

Media : Other, Water, Oil, Gas, Steam, Chemical fluids

Connection : Flanged / Threaded / Welded

Power : Manual / Pneumatic / Electric

Pressure : Other, PN16, PN25, Class 150, Class 300

Caliber : Full Bore / Reduced Bore

Two Way Ball Valves

Material : Stainless Steel

Media : Other, Water, Oil, Gas, Steam

Connection : Flanged

Power : Manual

Pressure : Other, Max 16 bar

Caliber : Standard

Single Piece Ball Valve

Material : Stainless Steel

Media : Other, Water, Oil, Gas, Steam

Connection : Screwed (BSP/NPT), Flanged

Power : Manual

Pressure : Other, Up to 40 Bar

Caliber : Full Bore

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry