|

Jacketed Ball Valves

Jacketed Ball Valves Specification

- Channels

- Single/Double

- Connection

- Flanged, Screwed, Welded

- Caliber

- Standard & Customized

- Pressure

- Class 150 to 900

- Material

- Stainless Steel, Carbon Steel, Alloy Steel

- Power

- Manual, Pneumatic, Electric

- Media

- Steam, Oil, Chemical, Water, Gas

- Temperature of Media

- Up to 400C

- Port Size

- 15mm to 300mm

- Flange

- ANSI, DIN, BS Standard

- Finish

- Polished or Painted

- Application

- Chemical processing, Oil & Gas, Pharmaceuticals, Food Industries

- Operation

- Lever, Gearbox, Actuator operated

- Jacket Pressure Rating

- Up to 10 bar

- End Connection Type

- Raised Face (RF), Ring Type Joint (RTJ), Butt Weld (BW)

- Face to Face

- ASME B16.10

- Jacket Material

- Mild Steel, Stainless Steel

- Leakage Class

- Class VI

- Corrosion Resistance

- High, suitable for aggressive fluids

- Blowout Proof Stem

- Available

- Design Standard

- ASME B16.34 / API 6D

- Sealing Material

- PTFE, Graphite

- Steam Jacket Inlet/Outlet

- Threaded or Flanged

- Fire Safe Design

- Available as per API 607

- Ball Material

- SS304/SS316

About Jacketed Ball Valves

Key points:

- Corrosion resistance and light in weight

- Easy to handle owing to their smooth surface finish

- Withstand high temperature and pressure

- Fast opening and closing operations

- Can be used both ways without any trouble

Further Details:

Our business provides a scope of Fully Jacketed Ball Valves that covers the structure from one rib to the next flange. Body is adjusted by including oversize spines. As illustration: 2" x 3" of our product has the ostensible drill of 2" (DN 50) as well as the rib extent is 3"(DN 80). Moreover, it permits enough area for bolting clearance.

Jacketed ball valves, guarantee steady valve cooling or heating of the procedure medium to avert seizing or crystallization of circulation media. It is exceptionally well outlines to help the elevated temperature oil flow or steam over the body parts of valve ball and valve ball itself to maintain the media fluid. This uses particularly to medium such as liquid sulfur and bitumen. Also, the proficient circulation of media is guaranteed through the removal of pockets.

Vapor, can be utilized as bearer for warming media. After quality affirmation principles, each valve is tried again following the Jackets are being soldered to body of the valve. Jacket air and hydraulic examined is done at 6000 grams per Cm2.

Typically, our jacketed ball valves are provided to the customers in carbon steel as well as in various sorts of stainless steel items. Other unique materials are additionally accessible upon particular demand.

Design & Testing International Standard:

- Size Range: ½" x 1" To 8" x 10"

- Valve Design: BS 5351 / ANSI B 16.34 / API 6D

- Pressure Testing: BS 6755 Part II / API 598 / API 6D

- Face To Face: As Per ANSI B 16.10

- Flange Drilling: ANSI B 16.5 / BS 10 Table / DIN / IS 6392

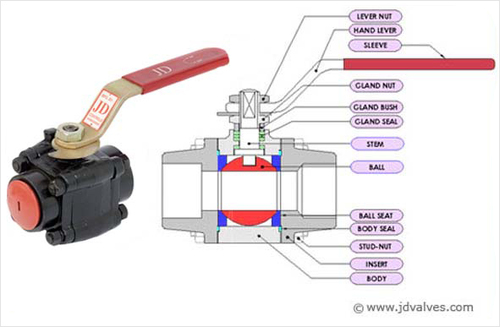

Material of Construction:

Body / Insert:

Cast Carbon Steel to ASTM A 216 GR. WCB

Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M

Ball:

Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M

Hast Alloy B / C

ASTM A 351 GR. CN 7M (Alloy 20)

Stem:

AISI 410 (S.S. 410 13% Cr. Steel)

AISI 304 (S.S. 304)

AISI 316 (S.S. 316)

AISI 304L (S.S. 304L)

AISI 316L (S.S. 316L)

Alloy 20

Hast Alloy B / C

Ball Seat / Gland Seal / Stem Seal:

P.T.F.E. Virgin

P.T.F.E. Glass Filled

P.T.F.E. Carbon Filled

Grafoil

Jacket Material:

S.S. 304, S.S. 316, S.S. 304L, S.S. 316L

M.S.

TECHNICAL SPECIFICATIONS:

Dimensions (150 class) All Dimension Are in mm

| Size | 15x20 | 25x40 | 25x50 | 40x65 | 50x80 | 65x100 | 80x100 | 100x150 | 150x250 |

| LF to F | 127 | 165.1 | 177.8 | 192 | 203 | 229 | 229 | 267 | 330.2 |

| ØG-NB | 12.5 | 25 | 25 | 40 | 50 | 63 | 75 | 100 | 150 |

| ØD | 108 | 127 | 152.4 | 177.8 | 190.5 | 228.6 | 228.6 | 279 | 406 |

| ØE | 79.2 | 98.5 | 120.6 | 139.7 | 152.4 | 190.5 | 190.5 | 241.3 | 361.95 |

| ØF | 50.8 | 73 | 92.1 | 104.7 | 127 | 157.2 | 157.2 | 215.9 | 323.08 |

| N | 4 | 4 | 4 | 4 | 8 | 8 | 8 | 8 | 12 |

| ØO | 15.8 | 15.8 | 19 | 19 | 19 | 19 | 19 | 22 | 25.4 |

| T | 11.1 | 14.3 | 15.8 | 17.7 | 19 | 23 | 23 | 25.4 | 30.23 |

Superior Temperature Control for Critical Applications

Jacketed ball valves are the ideal solution for process systems that require media heating or cooling during flow. The robust MS or SS jacket ensures uniform thermal management, making them well-suited for viscous, sensitive, or potentially solidifying fluids found in chemical, oil & gas, and food industries. Their high temperature and pressure resistance ensure reliable performance under stringent industrial demands.

Unmatched Corrosion Resistance & Longevity

With wetted parts available in SS304/SS316 and jacket materials in MS or SS, these ball valves offer outstanding corrosion resistance, suitable for aggressive chemicals or steam. Advanced sealing materials like PTFE and graphite further extend service life by minimizing leakage and wear. The fire-safe, blowout-proof design assures maximum operational safety.

FAQs of Jacketed Ball Valves:

Q: How do jacketed ball valves maintain process temperatures?

A: Jacketed ball valves use an external jacket made from mild or stainless steel to circulate steam or thermal fluid around the valve body. This maintains the desired process temperature, preventing solidification or viscosity increases in fluids such as chemicals, oils, or food products.Q: What standards do these jacketed ball valves comply with?

A: These valves are manufactured according to ASME B16.34 and API 6D design standards, with face-to-face dimensions compliant with ASME B16.10. Fire safe models also meet API 607 guidelines, ensuring global compatibility and exceptional safety.Q: When should I choose a jacketed ball valve with a specific sealing material?

A: PTFE sealing is recommended for applications needing high chemical resistance and lower friction. For higher-temperature or fire-safe requirements (up to 400C), graphite seals are preferable due to their superior heat tolerance and sealing properties.Q: Where are jacketed ball valves most beneficial in industrial settings?

A: They are particularly valuable in chemical processing, oil & gas, pharmaceuticals, and food industries, wherever temperature-sensitive or aggressive fluids need to be efficiently managed and safely isolated during processing or transfer.Q: What are the available operation modes for these valves?

A: Jacketed ball valves can be operated manually with a lever, through a gearbox for easier handling of larger sizes, or remotely via pneumatic or electric actuators, allowing for integration into automated systems.Q: How is leakage prevented in these jacketed ball valves?

A: These valves offer a Class VI leakage rating, the highest available, using advanced sealing materials and precise machining. The blowout-proof stem and fire-safe design further enhance safety and minimize the risk of valve failure under extreme conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

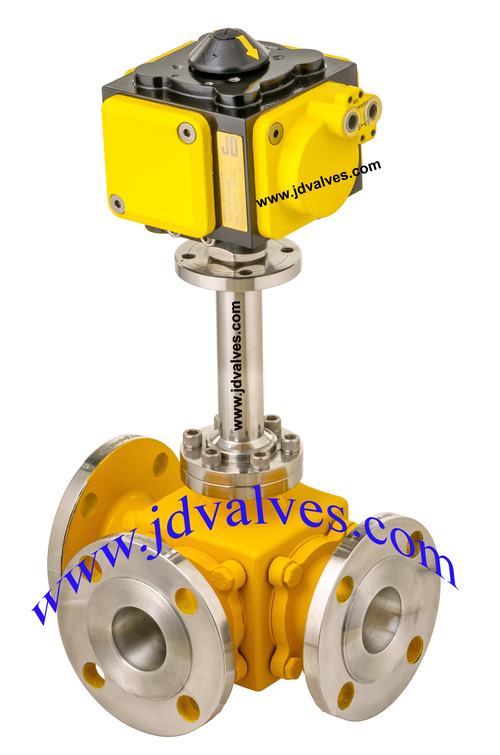

Three Way Ball Valves

Minimum Order Quantity : 1 Set

Finish : Polished / Painted / Powder Coated

Pressure : Other, PN16, PN25, PN40 or Class 150/300 (as per model)

Material : Other, Stainless Steel / Cast Steel / Carbon Steel / Brass / PVC

Media : Other, Water, Gas, Oil, Steam, Acid, Alkali

Structure : Other, Three Way

Forged Steel High Pressure Ball Valve

Finish : AntiCorrosion Coated

Pressure : Other, Up to 6000 PSI (420 bar)

Material : Other, Forged Steel

Media : Other, Water, Oil, Gas, Steam

Structure : Other, Ball Valve

Half Jacketed Ball Valve

Finish : Painted / Polished

Pressure : Other, Class 150/300/600/900 (PN10 to PN100)

Material : Other, Stainless Steel / Carbon Steel / Alloy Steel

Media : Other, Steam, Oil, Liquid, Gas, Chemical

Structure : Other, Ball Type, Two Piece

Pneumatic Actuator Operated 3 Way Ball Valve

Finish : Polished / Coated

Pressure : Other, Up to PN40 / 600 PSI

Material : Other, Stainless Steel / Cast Steel / Brass / PVC / CS (as per application)

Media : Other, Water, Air, Gas, Oil, Steam, Chemicals

Structure : Other, 3 Way Ball Valve

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry