|

Mounting Pad Ball Valves

Mounting Pad Ball Valves Specification

- Pressure

- PN16, PN25, Class 150, Class 300

- Structure

- Two Piece / Three Piece

- Caliber

- Full Bore / Reduced Bore

- Channels

- 1

- Connection

- Flanged / Threaded / Welded

- Material

- Stainless Steel / Carbon Steel / Cast Iron

- Power

- Manual / Pneumatic / Electric

- Media

- Water, Oil, Gas, Steam, Chemical fluids

- Temperature of Media

- -20C to 180C

- Port Size

- 1/2 to 8

- Flange

- ANSI, DIN, JIS Standard

- Finish

- Polished / Coated

- Application

- Industrial pipelines, water supply, chemical processing

About Mounting Pad Ball Valves

Mounting Pad Ball Valves

Our company provides best in class Mounting Pad Ball Valves which is produced with the help of advanced production technologies which gives excellent dimensional accuracy and greater structural stability. Heavy duty alloyed materials are used for the fabrication of this flow control unit that makes it capable to resist high temperature and pressure. The offered Mounting Pad Ball Valves can be easily controlled manually with the help of lever which fixed a ball that rotates within the pipe to open or close the flow channel.

Robust Design for Industrial Applications

Mounting Pad Ball Valves are meticulously crafted to handle a wide range of demanding applications, from water supply and chemical processing to oil and gas pipelines. Fire safe and anti-static body designs, combined with corrosion-resistant finishes, ensure long-lasting and safe operation even under harsh environmental conditions. The ISO 5211 mounting pad simplifies automation, supporting both manual and automated operation.

Versatile Connections and End Types

Choose from a variety of end types, including screwed, socket weld, butt weld, and flanged, compatible with ANSI, DIN, and JIS standards. The valves suit diverse installation requirements, making them ideal for new projects and retrofits in industrial settings. Available in full bore or reduced bore configurations, the flexible design ensures optimal flow and seamless integration in your pipeline.

Uncompromising Quality and Safety

Every valve is rigorously tested according to API 598 standards and built with fire safe features for additional peace of mind. Epoxy-coated or polished finishes provide added rust resistance, and anti-static designs protect against electrical discharge. With a lockable lever option, these ball valves prioritize user safety while maintaining ease of use and enduring performance.

FAQs of Mounting Pad Ball Valves:

Q: How does the ISO 5211 mounting pad enhance valve automation?

A: The ISO 5211 mounting pad design allows for effortless integration of automation devices such as pneumatic or electric actuators. This industry-standard interface ensures compatibility and simplifies the process of upgrading from manual to automated operation, resulting in improved efficiency in industrial pipelines.Q: What are the benefits of using PTFE, RPTFE, or PEEK seat materials in these valves?

A: PTFE and RPTFE seat materials offer excellent chemical resistance and low friction, making them ideal for water, steam, and chemical fluids. PEEK, on the other hand, provides superior mechanical strength and thermal stability, supporting higher temperatures and aggressive media, ensuring reliable and long-lasting valve performance.Q: When should I choose a full bore versus a reduced bore ball valve?

A: A full bore valve is preferable when minimal flow resistance and high flow rates are required, such as in transfer lines or process pipelines. Reduced bore valves, meanwhile, are suited for applications where flow control is more important than maximum throughput, offering cost savings and compact size.Q: Where can these ball valves be installed?

A: These ball valves are suitable for use in various industrial pipelines handling water, oil, gas, steam, and chemical fluids. Their robust construction and diverse end options make them ideal for installation in refineries, chemical plants, water treatment facilities, and general industrial environments.Q: What is the testing process for these valves, and how is safety ensured?

A: Each valve undergoes comprehensive testing as per API 598 standards, which includes pressure, leakage, and operational checks. Fire safe and anti-static features further enhance safety, ensuring performance under emergency and demanding conditions.Q: How does the lockable lever handle improve valve security?

A: The lockable lever handle prevents unauthorized or accidental operation by allowing the valve to be securely locked in the open or closed position. This is important in safety-critical or sensitive industrial environments, where process integrity must be maintained at all times.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

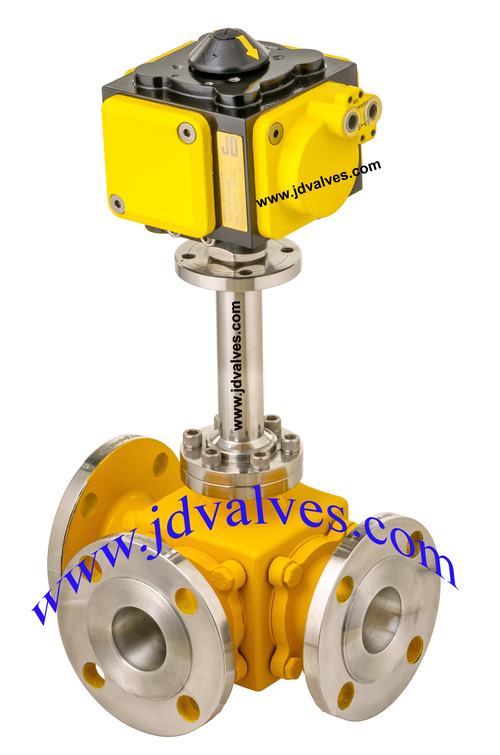

Three Way Ball Valves

Minimum Order Quantity : 1 Set

Material : Other, Stainless Steel / Cast Steel / Carbon Steel / Brass / PVC

Pressure : Other, PN16, PN25, PN40 or Class 150/300 (as per model)

Finish : Polished / Painted / Powder Coated

Structure : Other, Three Way

Connection : Flanged / Screwed / Socket Weld

Fire Safe Ball Valve

Material : Other, Stainless Steel / Carbon Steel

Pressure : Other, Class 150 to Class 800

Finish : Polished / Coated

Structure : Other, Ball Valve

Connection : Flanged / Screwed / Welded

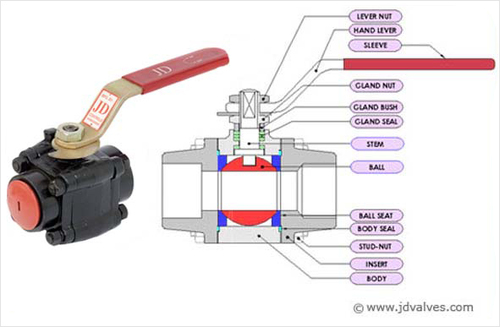

Forged Steel High Pressure Ball Valve

Material : Other, Forged Steel

Pressure : Other, Up to 6000 PSI (420 bar)

Finish : AntiCorrosion Coated

Structure : Other, Ball Valve

Connection : Screwed / Socket Weld / Flanged

4 Way Pneumatic Ball Valve

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Pressure : High Pressure

Structure : Control

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry