|

Fire Safe Ball Valve

Fire Safe Ball Valve Specification

- Structure

- Ball Valve

- Connection

- Flanged / Screwed / Welded

- Pressure

- Class 150 to Class 800

- Channels

- Single

- Caliber

- Full Bore

- Material

- Stainless Steel / Carbon Steel

- Power

- Manual

- Media

- Water, Oil, Gas, Chemical

- Port Size

- 1/2 to 12

- Flange

- ANSI, DIN, JIS Standard

- Finish

- Polished / Coated

- Application

- Fire Safe Applications, Industrial, Petrochemical

- Operation

- Quarter Turn

- Leakage Class

- Class VI

- Test Standard

- API 598

- Design Standard

- API 607, ISO 10497

- Body Seal

- Graphite

- Ball Material

- Stainless Steel

- Locking Device

- Available

- End Connection

- Threaded / Flanged / Butt Weld

- Seat Material

- PTFE / RPTFE

- Stem Material

- Stainless Steel

- Anti-Static Device

- Yes

- Blow-out Proof Stem

- Yes

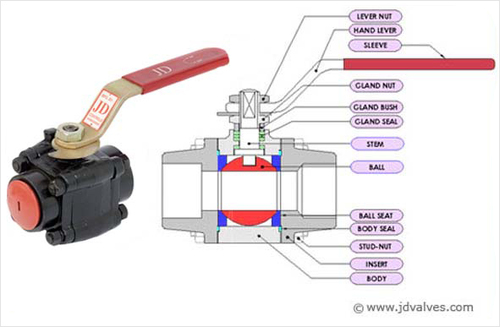

About Fire Safe Ball Valve

Fire Safe Ball Valve

Depending upon our sophisticated manufacturing facility, we are able to manufacture, supply and export superior quality range of Fire Safe Ball Valve. This safe ball valve is leak resistant, corrosion resistant and easy to maintain & install due to which it is highly appraised among our clients at global level. Fine Safe Ball Valve is manufactured using high grade quality components sourced from the reputed vendors of market. We offer this range of ball valve at industry leading prices.

Our company offers fire safe ball valve that is designed and made in compliance with API standard in reduced and full port along with blown out safe stem as well as antistatic device with different alternatives of working.

Trunnion and Floating Mounted

Both floating and trunnion mounted fire safe ball valve is provided by our company. In the drifting ball plan, where fixing happens by permitting the Ball below weight to change place towards the down seat to impact tight seal. Further, for elevated pressure and sizes appraisals ball valves of trunnion mounted are favored by industry.

Valve Working

Our fire safe ball valves are normally provided with Gear Operated or hand-operated Hand Lever, contingent upon valve measure. It is available with either Electrical actuator worked for mechanization or Pneumatic (Single Acting/Double Acting Spring Return).

Variety Of Body Seat, Packing And Seal

Our product is additionally accessible with various sort of Seat, packing and Seal material, for example, P.T.F.E. (pure)/Carbon Filled (PTFE)/PEEK/Glass Filled (PTFE)/ Graphite (grafoil) to meet particular demand of customer.

Striking Features:

- Blowout safe Stem

- Anti Static Instrument

- Fire Protected Seat Design

- Twofold Body Sealing makes sure Positive structure Joint fixing from Pipeline tensions

- Different Stem Sealing

- Live stacked Stem plan matches vigorous Fugitive Norms

- Particularly outlined seals and seats in an assortment of materials to meet particular usages

- Fire Protected outline Affirms to API 607

- Valves are fire safe and tested ensured by Bureau Veritas.

- Plan standard API 6D, ANSI B16.34 and BS EN ISO 17292

- Valves with Lengthy Stems and for Underground Applications , Multiport Fire secured Ball Valves, and so on, additionally accessible on demand.

Design & Testing International Standard:

Valve Design: BS EN ISO 17292 (BS 5351) / API 6D / ASME B 16.34 / BE EN ISO 12516

Pressure Testing: API 598 / API 6D / BS EN 12266 I

Fire Testing: API 607 / BS EN ISO 1266 II

Face To Face: As Per ANSI B 16.10

Flange Drilling: ANSI B 16.5, Raised Face, Class 150 / 300 / 600

Screwed End: ANSI B 1.20.1 (BSP/NPT)

Socket Weld End: ANSI B 16.11

Butt Weld End: ANSI B 16.25

Quality Assurance:ISO 9001

Material of Construction:

Body / End Connector Piece:

Cast Carbon Steel to ASTM A 216 GR. WCB

Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M

Hast Alloy B / C

ASTM A 351 GR. CN 7M (Alloy 20)

Ball:

Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M

Hast Alloy B / C

ASTM A 351 GR. CN 7M (Alloy 20)

Stem:

AISI 304 (S.S. 304)

AISI 316 (S.S. 316)

AISI 304L (S.S. 304L)

AISI 316L (S.S. 316L)

Hast Alloy B / C

Alloy 20

Ball Seat / Gland Seal / Stem Seal:

P.T.F.E. Glass Filled

P.T.F.E. Carbon Filled

Grafoil / Graphite Ring

P.T.F.E. Virgin

| Size | Inch | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| DN | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |

| L-F to F-Short | 107.9 | 117.3 | 127 | 165.1 | 177.8 | 192 | 203 | 229 | 267 | 292 | 330 | - | |

| L1-F to F-Long | - | - | - | - | - | - | - | - | 394 | 457 | 533.4 | 609.6 | |

| G-NB | 12.5 | 19 | 25 | 38 | 50 | 63 | 75 | 100 | 150 | 200 | 250 | 300 | |

| D | 89 | 98.5 | 108 | 127 | 152.6 | 177.8 | 190.5 | 228.6 | 279 | 343 | 406 | 483 | |

| E | 60.3 | 69.8 | 79.3 | 98.4 | 120.6 | 139.7 | 152.4 | 190.5 | 241.3 | 298.4 | 362 | 431.8 | |

| F | 35 | 43 | 50.8 | 73 | 92.1 | 104.7 | 127 | 157.2 | 215.9 | 269.9 | 323.8 | 381 | |

| N | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 8 | 8 | 8 | 12 | 12 | |

| O | 15.8 | 15.8 | 15.8 | 15.8 | 19 | 19 | 19 | 19 | 22.2 | 22.2 | 25.4 | 25.4 | |

| T | 10.2 | 10.5 | 11.2 | 14.5 | 15.8 | 17.5 | 19 | 23.8 | 25.4 | 28.4 | 30.23 | 31.75 | |

Tested for Fire Safety and Reliability

Each valve is rigorously tested according to API 598, API 607, and ISO 10497 standards. The integration of fire-safe technology and graphite body seals ensures operational integrity even under extreme heat, making it suitable for fire-safe and hazardous industrial installations.

Versatile Material and Design Options

Available in stainless steel and carbon steel, the Fire Safe Ball Valve accommodates diverse process requirements. Customers can select from various port sizes (1/2" to 12"), connection types (flanged, threaded, welded), and international flange standards (ANSI, DIN, JIS) to fit any configuration.

Enhanced Safety Mechanisms

Equipped with a blow-out proof stem, anti-static device, and lockable handle, this valve prioritizes operational safety. These features safeguard against accidental disassembly, static-induced ignition, and unauthorized operation in critical applications.

FAQs of Fire Safe Ball Valve:

Q: How does the Fire Safe Ball Valve ensure safety in high-temperature or fire conditions?

A: The valve is certified to API 607 and ISO 10497 fire-safe standards, utilizing graphite body seals and robust seat materials (PTFE/RPTFE). These features maintain sealing integrity during and after exposure to high temperatures, significantly reducing leakage risks in fire emergencies.Q: What media are compatible with this ball valve, and where can it be used?

A: It is suitable for various media, including water, oil, gas, and chemicals. Commonly used in fire-prone or hazardous environments, the valve is ideal for applications in industrial, petrochemical, and process industries requiring stringent fire safety compliance.Q: When should I choose a full bore valve for my application?

A: Full bore valves are recommended when minimal flow restriction and pressure drop are crucial. They are perfect for processes demanding high flow rates or applications where pigging (maintenance cleaning) is required.Q: What standards does the valve comply with, and why are they important?

A: The valve adheres to API 607, ISO 10497 for fire safety; API 598 for pressure testing; and leakage Class VI for zero leakage. Compliance with these international standards guarantees high performance and safety in demanding working conditions.Q: How does the anti-static device benefit industrial applications?

A: The integrated anti-static device prevents the build-up of static electricity between the ball, stem, and body, reducing potential ignition risks in volatile environments and ensuring safer operation.Q: What process is followed during inspection and testing before delivery?

A: Each valve undergoes stringent pressure, fire-safe, and leakage tests as per API 598 and fire-test protocols. This guarantees reliable, leak-free performance upon installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

Jacketed 3 Way Ball Valve

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Application : Chemical, Petrochemical, Food, Pharmaceutical Industries

Power : Manual

Pressure : Other, PN16 to PN40

Connection : Flanged

Pneumatic Ball Valve

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Application : Industrial, Chemical, Water Treatment, Oil & Gas

Power : Pneumatic

Pressure : Other, PN16 / PN25 / 150PSI

Connection : Flanged

Forged Steel High Pressure Ball Valve

Material : Other, Forged Steel

Application : Industrial, Petrochemical, Power Plants, High Pressure Systems

Power : Manual

Pressure : Other, Up to 6000 PSI (420 bar)

Connection : Screwed / Socket Weld / Flanged

Jacketed Ball Valves

Material : Other, Stainless Steel, Carbon Steel, Alloy Steel

Application : Chemical processing, Oil & Gas, Pharmaceuticals, Food Industries

Power : Manual, Pneumatic, Electric

Pressure : Other, Class 150 to 900

Connection : Flanged, Screwed, Welded

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry