|

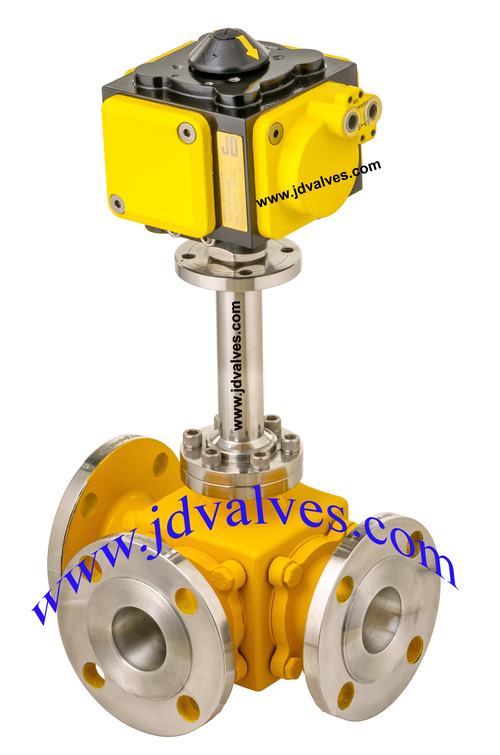

Three Way Ball Valves

Price 1064 INR/ Set

Three Way Ball Valves Specification

- Structure

- Three Way

- Connection

- Flanged / Screwed / Socket Weld

- Pressure

- PN16, PN25, PN40 or Class 150/300 (as per model)

- Channels

- T Port / L Port

- Material

- Stainless Steel / Cast Steel / Carbon Steel / Brass / PVC

- Power

- Manual / Pneumatic / Electric

- Media

- Water, Gas, Oil, Steam, Acid, Alkali

- Port Size

- 1/2 to 6 (DN15 to DN150)

- Flange

- ANSI / DIN / JIS Standard

- Finish

- Polished / Painted / Powder Coated

- Application

- Industrial / Chemical / Water Treatment / Petrochemical / HVAC

Three Way Ball Valves Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1 Set Per Day

- Delivery Time

- 1 Week

About Three Way Ball Valves

Three Way Ball Valves

We are a well-known manufacturer, exporter and supplier of a high quality range of Three Way Ball Valves that are used for controlling the movement and pressure of various types of liquids and gases. In order to manufacture these valves, best-in-class raw material and modern technology is used by our experienced engineers in compliance with international standards. These valves are available in varied sizes and other specifications as per the needs of the clients. We offer Three Way Ball Valves at industry leading rates to the clients.

Three Way Ball Valve is available with either T Port or L Port for reasonable service state. Diverting and Mixing sort is additionally accessible for the customers. Four Way Ball Valve is accessible with Two L Port. Further, the four way and three way Ball Valve highlights four seats for equivalent seat loading. Various spring washer and Gland Packing Seal provides zero spillage from gland portion.

J. D. Covers extent array for Multiport Ball Valve in Socket/ butt solder end/ screwed as well as in Flanged End from to 6, Force Rating approx. 300.

J. D. P.T.F.E. placed Ball Valves provides tight shut off, less torque with simple working and Zero Leakage at temperature running between - 20° C. to +220° C. In addition, Electro-Polished, Ultra Clean and Buff Finish additionally given Pharmaceutical and Food Industries on demand.

Key Features:

-

High efficiency

-

Strong construction

-

High tensile strength

-

Compact design

Specifications:

| Salient Features: | |

| Low Pressure Drop | Compact Design |

| Simplicity | Longer Life |

| High Performance Ball Valve | Positive Shut off |

| Without Lubrication | Quick in Action |

| Design & Testing International Standard: | |

| Valve Design | BS 5351 / ANSI B 16.34 / API 6D |

| Pressure Testing | BS 6755 Part II / API 598 / API 6D |

| Face To Face | Mfg. Standard |

| Flange Drilling | ANSI B 16.5 / BS 10 Table / DIN / IS 6392 |

| Butt Weld End | ANSI B 16.25 |

| Socket Weld End | ANSI B 16.11 |

| Screwed End | ANSI B 1.20.1(BSP/NPT) |

Material of Construction:

| Body / End Connector Piece: |

| Cast Iron to ASTM A 126 Class B IS 210 GR. FG 200 / 220 / 260 |

| Ductile Iron to ASTM A 536 Grade 65-45-12 |

| Cast Carbon Steel to ASTM A 216 GR. WCB |

| Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M |

| Hast Alloy B / C |

| ASTM A 351 GR. CN 7M (Alloy 20) |

| Ball: |

| Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M |

| Hast Alloy B / C |

| ASTM A 351 GR. CN 7M (Alloy 20) |

| Stem: |

| AISI 410 (S.S. 410 13% Cr. Steel) |

| AISI 304 (S.S. 304) |

| AISI 316 (S.S. 316) |

| AISI 304L (S.S. 304L) |

| AISI 316L (S.S. 316L) |

| Hast Alloy B / C |

| Alloy 20 |

| Ball Seat / Gland Seal / Stem Seal |

| P.T.F.E. Virgin |

| P.T.F.E. Glass Filled |

| P.T.F.E. Carbon Filled |

Versatile Flow Control Solutions

These three way ball valves facilitate mixing or diverting flow in piping systems, making them ideal for industrial, chemical, and water treatment applications. With T or L port channels, you can redirect or combine media efficiently, enhancing system flexibility.

Durability Meets Precision Engineering

Built with robust materialsstainless steel, cast steel, carbon steel, brass, or PVCthese valves ensure longevity under harsh conditions. PTFE and other advanced seat options provide chemical resistance and minimal leakage (Class VI), while the antistatic device and blow-out proof stem ensure operational reliability.

FAQs of Three Way Ball Valves:

Q: How do three way ball valves operate in mixing and diverting applications?

A: These ball valves use a quarter-turn design and feature T port or L port channels to either mix two fluid streams into one or divert flow between two outlets. This flexibility enables efficient modulation of fluids in complex piping layouts.Q: What sealing materials are available and what are their advantages?

A: You can choose from PTFE, RPTFE, PEEK, or metal seats. PTFE and RPTFE provide excellent chemical resistance and low friction, ideal for corrosive or clean media. PEEK suits high temperatures and aggressive chemicals, while metal seats are preferred for abrasive or high-pressure environments.Q: Where can these three way ball valves be installed?

A: These valves are suitable for a range of locations, including industrial plants, water treatment facilities, HVAC systems, petrochemical sites, and chemical processing lines. Their diverse end connections accommodate various installation standards such as ANSI, DIN, and JIS.Q: What is the process for selecting the correct flow pattern and port design?

A: Determining whether you require a T port or L port depends on your flow requirementchoose T port for mixing or 3-way diverting, and L port for two-way diverting applications. Review your systems fluid flow diagrams to select the appropriate configuration.Q: What benefits do antistatic devices and blow-out proof stems provide?

A: Antistatic devices prevent static electricity build-up, reducing explosion risks in flammable media, while blow-out proof stems ensure the valve stem remains securely in place under pressure, enhancing safety and service life.Q: Which power and handle options are available for actuation?

A: These ball valves can be operated manually (with stainless steel or plastic-coated handles), or automated using pneumatic or electric actuators, depending on system requirements and user preference.Q: When should you use flanged versus threaded or weld end connections?

A: Flanged connections are ideal for large diameters or systems requiring frequent maintenance, while threaded and weld ends are better for compact, high-pressure, or permanent installations. The choice depends on system standards (ANSI, DIN, JIS) and operational needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

Mounting Pad Ball Valves

Material : Other, Stainless Steel / Carbon Steel / Cast Iron

Finish : Polished / Coated

Structure : Other, Two Piece / Three Piece

Pressure : Other, PN16, PN25, Class 150, Class 300

Media : Other, Water, Oil, Gas, Steam, Chemical fluids

Fire Safe Ball Valve

Material : Other, Stainless Steel / Carbon Steel

Finish : Polished / Coated

Structure : Other, Ball Valve

Pressure : Other, Class 150 to Class 800

Media : Other, Water, Oil, Gas, Chemical

3 Way Gear Operated Ball Valve

Material : Other, Stainless Steel / Carbon Steel / Alloy Steel

Finish : Shot Blasted, Painted, or As Required

Structure : Other, 3 Way Ball Valve

Pressure : Other, 150# / 300# / 600#

Media : Other, Water, Gas, Oil, Steam, Chemicals

Automation Series Ball Valve

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Finish : Polished

Structure : Control

Media : Water

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry