|

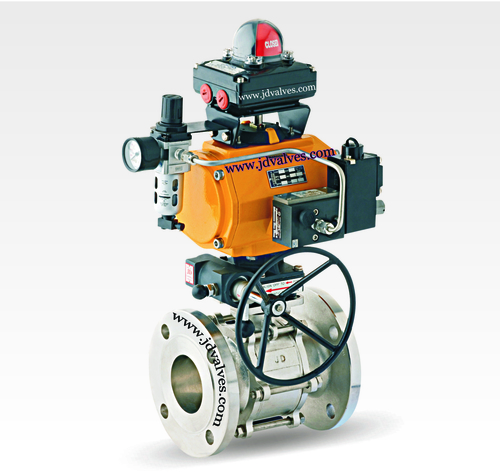

Two Way Ball Valves

Two Way Ball Valves Specification

- Connection

- Flanged

- Caliber

- Standard

- Structure

- Two Way

- Channels

- 2

- Pressure

- Max 16 bar

- Material

- Stainless Steel

- Power

- Manual

- Media

- Water, Oil, Gas, Steam

- Temperature of Media

- Up to 180C

- Port Size

- 1/2 to 4

- Flange

- ANSI, DIN, JIS Standards

- Finish

- Polished

- Application

- Industrial, Chemical, Water Supply

- End Connection

- Flange End

- Flow Characteristic

- Unobstructed Straight Flow

- Handle Type

- Lever Operated

- Body Design

- Split Body

- Mounting

- ISO Standard Mounting

- Seat Material

- PTFE

- Leakage Class

- Class VI

- Valve Type

- Full Bore Ball Valve

- Service Life

- Long Service Life

- Testing Standard

- API 598

- Coating

- Electropolished Finish

- Size Range

- DN15-DN100

- Operation

- Quarter Turn

About Two Way Ball Valves

Two Way Ball Valves

Leveraging on the support of our dexterous workforce, we are able to manufacture, supply, and exports a large range of Two Way Ball Valves. These are manufactured to control the free flow of fluids. These are available with a handle which is used for opening and closing of the valve. Easy to fit, these valves are fundamentally used in entire industrial catalog. Moreover, post production these Two Way Ball Valves undergo stringent quality check to ensure flawlessness.

Special Alternatives:

- Developed Bonnet Sort

- Incomplete/Complete Jacketed Ball Valve

- Handle Protection System

- P.T.F.E. (FEP/PFA) Seamed Ball Valve

- Flush Base Plan Ball Valve

- Various Port Ball Valve (four And Three Way)

- Ball Valve Of Polypropylene Material

- Ball Valve Of Tri-Clover End

- Pneumatic Turning Actuator Directed Ball Valve

- Custom Made Ball Valve

Technical Details:

| Special Features: |

| Low Pressure Drop |

| No Lubrication |

| Close Indication Simplicity |

| High Performance Ball Valve |

| Positive Shut off |

| Quick in Action |

| Material of Construction: | |

| End Connection | Screwed AS PER BSP/BSPT/NPT |

| Cast Carbon Steel | ASTM A 216 Gr WCB |

| Cast Stainless Steel | ASTM A 351 Gr CF 8/CF 8M |

| Size Range | 6 mm to 150 mm |

| Socketweld | AS PER ANSI B 16.11 |

| Cast Iron | IS 210 Gr FG 200 |

| Pressure Rating | ASA 125#, 150#, 800# |

| Engineering Option | Gear Operated, Electrical Actuated, Pneumatic Actuated |

| Flanged | AS PER ANSI B 16.5 |

| Design & Testing International Standard: | |

| Screwed End | ANSI B 1.20.1(BSP/NPT) |

| Butt Weld End | ANSI B 16.25 |

| Face To Face | ANSI B 16.10 |

| Pressure Testing | BS 6755 Part II / API 598 / API 6D |

| Valve Design | BS 5351 / ANSI B 16.34 / API 6D |

| Flange Drilling | ANSI B 16.5 / BS 10 Table / DIN / IS 6392 |

| Socket Weld End | ANSI B 16.11 |

| Fire Safe Testing | BS 6755 Part II API 607 / API 6FA / |

Robust Design and Reliable Operation

Constructed with a split body and full bore flow path, these valves ensure minimal pressure drop and a robust, leak-proof seal. The PTFE seat material offers chemical resistance and durability, making them suitable for aggressive and high-temperature media. Their long service life and reliable performance reduce maintenance needs and operational costs.

Versatile Application and Quality Assurance

These ball valves comply with ANSI, DIN, and JIS flange standards, making them adaptable across various industrial systems. Each valve undergoes rigorous API 598 testing to ensure Class VI leakage performance. With their ISO standard mounting and polished finish, they are both easy to install and maintain, suitable for water, oil, gas, and steam up to 180C.

FAQs of Two Way Ball Valves:

Q: How should a full bore two way ball valve with flanged ends be installed?

A: Installation involves aligning the flange ends of the valve with the corresponding pipe flanges, ensuring the gasket is in place, and securing the connection with appropriate bolts. ISO standard mounting facilitates compatibility with actuators if needed.Q: What are the main benefits of electropolished stainless steel for these ball valves?

A: An electropolished finish enhances corrosion resistance, provides a smoother surface to reduce buildup, and improves hygiene, making the valve ideal for critical industrial and chemical environments.Q: When should I choose a split body, lever-operated ball valve for my application?

A: A split body, lever-operated valve is ideal when frequent maintenance or inspection is required, as the design allows easy access to internal components. Lever operation ensures quick and precise quarter-turn control for immediate shutoff or flow adjustments.Q: Where can these full bore ball valves be utilized?

A: These valves are suitable for a wide range of applications, including industrial processes, chemical plants, water treatment facilities, and steam systems, where reliable, leak-tight shutoff and compatibility with water, oil, gas, or steam are essential.Q: What is the process for testing these valves according to API 598?

A: Each valve undergoes pressure and leakage tests specified by API 598, ensuring reliable performance and compliance with Class VI leakage standards before dispatch.Q: How does the unobstructed straight flow characteristic benefit system performance?

A: The full bore design ensures minimal pressure loss and allows media to pass through without obstruction, improving flow efficiency and reducing wear within your piping system.Q: What is the maximum operational pressure and temperature for these valves?

A: These ball valves handle pressures up to 16 bar and media temperatures up to 180C, making them suitable for demanding industrial, chemical, and water supply applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

Mounting Pad Ball Valves

Pressure : Other, PN16, PN25, Class 150, Class 300

Material : Other, Stainless Steel / Carbon Steel / Cast Iron

Finish : Polished / Coated

Structure : Other, Two Piece / Three Piece

Application : Industrial pipelines, water supply, chemical processing

Media : Other, Water, Oil, Gas, Steam, Chemical fluids

Fire Safe Ball Valve

Pressure : Other, Class 150 to Class 800

Material : Other, Stainless Steel / Carbon Steel

Finish : Polished / Coated

Structure : Other, Ball Valve

Application : Fire Safe Applications, Industrial, Petrochemical

Media : Other, Water, Oil, Gas, Chemical

Pneumatic Actuator Operated Wafer Type Ball Valve

Pressure : Other, PN16 / 150#

Material : Other, CF8M Stainless Steel

Finish : Polished

Structure : Other, Wafer Type Ball Valve

Application : Industrial Process Automation, Water Treatment Plants, Chemical Industries

Media : Other, Water, Gas, Oil, Steam, Chemicals

3 Piece Ball Valves

Pressure : High Pressure

Material : Stainless Steel

Finish : Polished

Structure : Control

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry