|

Industrial Control Valve

Industrial Control Valve Specification

- Structure

- Globe Type

- Material

- Cast Steel

- Power

- Pneumatic

- Pressure

- 10 Bar

- Media

- Water, Air, Gas, Oil

- Port Size

- 1/2 inch to 8 inch

- Surface

- Polished

- Shape

- Straight

- Application

- Industrial Automation, Fluid Handling, Process Control

- Seal Material

- PTFE

- End Connection

- Flanged Ends

- Control Signal

- 4-20 mA / Pneumatic

- Actuator Type

- Pneumatic Actuator

- Operating Method

- Automatic/Manual

- Flow Characteristic

- Equal Percentage / Linear

- Body Material

- Carbon Steel

- Valve Type

- 2 Way / 3 Way

- Connection Type

- Flanged

- Leakage Class

- IV (Standard)

- Port Connection

- DIN / ANSI Standard

Industrial Control Valve Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Day

- Delivery Time

- 1 Days

About Industrial Control Valve

Industrial Control Valve

Innovation is our forte and for this we manufacture, supply and export Industrial Control Valve. These valves are appreciated by the industry for facilitating in controlling running liquid and gases components. We manufacture our valves using premium quality raw material to ensure that final output meets with international quality norms. In order to meet the specific requirements of our esteemed clients, we provide an option of customization for our Industrial Control Valve.

Key Features:

- Sturdy built

- Tamper proof

- Long lasting

- Corrosion resistant

Versatile Control for Industrial Automation

Designed for seamless integration in industrial automation, this control valve is ideal for regulating the flow of diverse media including water, air, gas, and oil. Its straight, globe-type construction and flanged connections simplify installation across various industrial settings, ensuring robust performance and adaptability.

Precision and Reliability with Pneumatic Actuation

The pneumatic actuator ensures rapid and reliable valve operation, suitable for both automatic and manual control processes. With compatibility for both equal percentage and linear flow characteristics, process engineers can fine-tune control to meet diverse system requirements in industrial environments.

Engineered for Durability and Safety

Crafted from cast carbon steel and sealed with PTFE, the valve offers corrosion resistance and durability even in demanding operating conditions. The leakage class IV rating and up to 10 bar pressure capacity safeguard your process integrity, minimizing downtime and ensuring a safe, leak-free experience.

FAQs of Industrial Control Valve:

Q: How does the Industrial Control Valve operate with both automatic and manual methods?

A: This control valve can be operated automatically using a pneumatic actuator driven by a 4-20 mA or pneumatic signal, allowing for precise remote control. Alternatively, manual override is possible when on-site adjustments or maintenance are required.Q: What types of industries and applications can benefit from this valve?

A: Our industrial control valve is well-suited for process control, fluid handling, and industrial automation in sectors such as oil and gas, water treatment, chemical processing, and general manufacturing, where accurate flow regulation is essential.Q: When should I choose a 2-way versus a 3-way valve configuration?

A: A 2-way valve is optimal for simple flow on/off control, while a 3-way valve is recommended when mixing or diverting fluid streams is required. The correct selection depends on your process requirements.Q: Where can this valve be installed regarding end connections and standards?

A: The valve is designed with flanged ends compatible with both DIN and ANSI international standards, fitting seamlessly into new or existing piping systems across a wide range of industrial facilities.Q: What is the expected process for installation and commissioning?

A: Installation involves aligning the flanged ends with corresponding pipe flanges, securing with bolts, and connecting to the pneumatic actuator and control system. Calibration ensures accurate response to control signals for optimal process performance.Q: How does the PTFE seal and class IV leakage rating benefit system reliability?

A: PTFE seals provide excellent chemical and temperature resistance, ensuring durability. The class IV leakage rating signifies very low allowable leakage, which reduces product loss and enhances process safety.Q: What advantages do the equal percentage and linear flow characteristics offer?

A: Equal percentage flow is ideal for processes needing precise control over a wide range, while linear flow simplifies proportional adjustments. Both options help optimize process efficiency and response according to system needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Valve Category

Swing Check Valves

Minimum Order Quantity : 1 Set

Port Size : 2 to 24 (Inches)

Surface : Other, Red Epoxy Coated

Pressure : High Pressure Bar

Media : Water

Shape : Swing Type

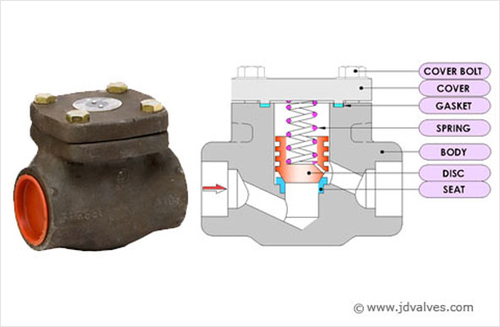

Forged Steel Check Valve

Minimum Order Quantity : 500 Sets

Port Size : 1/2 inch to 2 inches

Surface : Other, Anticorrosive Coated

Pressure : Other, Up to 800 lbs

Media : Other, Water, Oil, Steam, Gas

Shape : Ypattern / Tpattern

Diaphragm Valves

Minimum Order Quantity : 1 Set

Port Size : 15mm to 300mm

Surface : Other, Epoxy Painted, Polished

Pressure : Medium Pressure

Media : Other, Water, Gas, Oil, Chemicals

Shape : Straight/Angle

Slurry Valves

Minimum Order Quantity : 1 Set

Port Size : 2 Inch

Surface : Other, Polished

Pressure : High Pressure

Media : Other, Slurry

Shape : Round

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry