|

Pneumatic Actuator Operated Wafer Type Ball Valve

Pneumatic Actuator Operated Wafer Type Ball Valve Specification

- Caliber

- Full Bore

- Channels

- Single Channel

- Connection

- Wafer Connection

- Structure

- Wafer Type Ball Valve

- Pressure

- PN16 / 150#

- Material

- CF8M Stainless Steel

- Power

- Pneumatic

- Media

- Water, Gas, Oil, Steam, Chemicals

- Port Size

- 1 inch to 6 inch

- Flange

- ASME/ANSI B16.5

- Finish

- Polished

- Application

- Industrial Process Automation, Water Treatment Plants, Chemical Industries

About Pneumatic Actuator Operated Wafer Type Ball Valve

Pneumatic Actuator Operated Wafer Type Ball Valve

We feel immense proud to introduce our business in this domain as an acclaimed manufacturer, exporter and supplier of Pneumatic Actuator Operated Wafer Type Ball Valve. The provided valve is well-suited for fitted in various gas and fluids plants to control the process flow. This valve is manufactured with the utilization of quality-approved raw materials and advanced techniques under the stern guidance of our deft professionals. Further, this Pneumatic Actuator Operated Wafer Type Ball Valve can be purchased by our clients at industry leading prices.

Key Features:

- Robust construction

- Hassle free functioning

- High durability

- Easy to fit

Precision Engineering for Demanding Applications

Built to the highest standards, this wafer type ball valve ensures reliable shut-off and flow control for a broad range of industrial applications. Its Class VI leakage rating, full bore design, and robust pressure tolerance guarantee operational integrity while the electropolished CF8M body ensures superior corrosion resistance. The actuator delivers rapid, repeatable operation for both on/off and modulating process requirements.

Flexible Connection and Installation

Engineered with wafer-style connections for installation between flanges (ASME/ANSI B16.5), the valve facilitates easy integration into existing pipe systems. The ISO 5211 mounting interface allows for straightforward actuator attachment, streamlining setup in both new builds and retrofit projects. Port sizes from 1 inch to 6 inches provide versatility across various flow capacities.

FAQs of Pneumatic Actuator Operated Wafer Type Ball Valve:

Q: How does the double acting pneumatic actuator work in this wafer type ball valve?

A: The double acting pneumatic actuator uses compressed air to open and close the valve by moving the SS316 ball. Air pressure applied alternately to each side of the actuator piston controls the precise on/off or modulating operation, ensuring rapid response within less than one second.Q: What are the main benefits of the PTFE seat and SS316 ball materials in this valve?

A: PTFE seat material offers excellent chemical resistance and low friction, while the SS316 ball provides durability and corrosion resistance. This combination ensures reliable sealing, smooth operation, and extended service life even with aggressive media such as steam, chemicals, oils, and water.Q: Where can this pneumatic wafer type ball valve be used effectively?

A: This valve is ideal for industrial process automation, water treatment plants, and chemical industries. Its durability, corrosion resistance, and compatibility with a variety of media make it suitable for demanding environments where dependable on/off or modulating control is required.Q: What is the leakage class of this valve, and why is it important?

A: The valve is rated at Leakage Class VI, indicating bubble-tight shut-off performance. This prevents process losses, reduces maintenance, and increases safety, particularly in applications handling hazardous or costly media.Q: When should I choose a wafer connection over other valve end types?

A: Wafer connections are chosen when easy installation between pipe flanges and a compact form factor are needed. They reduce space requirements and simplify maintenance, making them ideal for systems adhering to ASME/ANSI B16.5 standards.Q: How does surface electropolishing benefit the valves performance?

A: Electropolished surfaces improve corrosion resistance, reduce the buildup of contaminants, and facilitate easier cleaning. This finish is especially beneficial in applications involving aggressive chemicals or strict hygiene standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

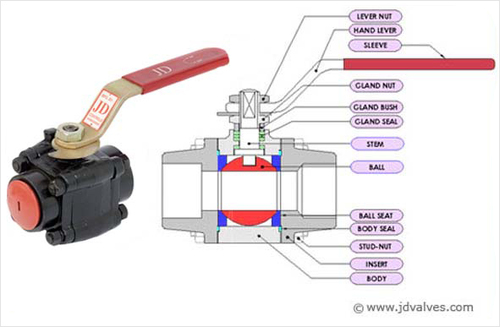

Forged Steel High Pressure Ball Valve

Finish : AntiCorrosion Coated

Material : Other, Forged Steel

Pressure : Other, Up to 6000 PSI (420 bar)

Application : Industrial, Petrochemical, Power Plants, High Pressure Systems

Media : Other, Water, Oil, Gas, Steam

Caliber : High Precision Caliber

Jacketed Ball Valves

Finish : Polished or Painted

Material : Other, Stainless Steel, Carbon Steel, Alloy Steel

Pressure : Other, Class 150 to 900

Application : Chemical processing, Oil & Gas, Pharmaceuticals, Food Industries

Media : Other, Steam, Oil, Chemical, Water, Gas

Caliber : Standard & Customized

Half Jacketed Ball Valve

Finish : Painted / Polished

Material : Other, Stainless Steel / Carbon Steel / Alloy Steel

Pressure : Other, Class 150/300/600/900 (PN10 to PN100)

Application : Chemical, Petrochemicals, Oil & Gas, Pharmaceutical, Food & Beverage, Process Industry

Media : Other, Steam, Oil, Liquid, Gas, Chemical

Caliber : Full Bore / Reduced Bore

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry