|

Jacketed 3 Way Ball Valve

Jacketed 3 Way Ball Valve Specification

- Channels

- Three

- Pressure

- PN16 to PN40

- Caliber

- Full Bore

- Structure

- 3 Way Ball Valve

- Connection

- Flanged

- Material

- Stainless Steel

- Power

- Manual

- Media

- Water, Oil, Gas, Steam, Chemicals

- Temperature of Media

- -20C to 180C

- Port Size

- 1/2 to 12

- Flange

- ANSI, DIN, JIS Standard

- Finish

- Jacketed, Polished

- Application

- Chemical, Petrochemical, Food, Pharmaceutical Industries

- Blowout Proof Stem

- Yes

- Body Coat

- Anti-Corrosion Painted

- Testing Standard

- API 598

- Jacket Pressure Rating

- Max. 10 Bar

- Seat Material

- PTFE, CFT, PEEK

- Leakage Class

- Class VI

- Design Standard

- ASME B16.34, API 6D

- Flow Pattern

- L or T Port

- End Connection

- Flanged, Butt Weld

- Ball Material

- Stainless Steel SS304/SS316

- Mounting Pad

- ISO 5211

- Jacket Material

- Carbon Steel or Stainless Steel

- Operation

- Lever Operated

Jacketed 3 Way Ball Valve Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Sets Per Week

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Main Export Market(s)

- Western Europe, Middle East, Central America, Eastern Europe, North America

- Main Domestic Market

- All India

About Jacketed 3 Way Ball Valve

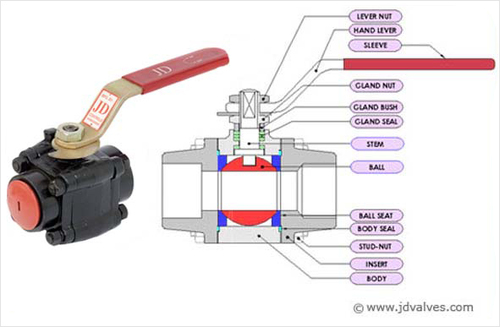

Jacketed 3 Way Ball Valve

We have an enviable reputation as a global manufacturer and supplier of Jacketed 3 Way Ball Valve. To obtain 100% client satisfaction, our offered 3 way ball valve is manufactured using international quality and standards. Jacketed Three Way Ball Valve is renowned for its resistance to abrasion, durability and long functional life. This 3 way ball valve is manufactured using quality materials procured from the trusted vendor of the market. This valve is available at affordable prices for our valued customers.

Advanced Jacketed Ball Valve Engineering

This 3 way ball valve is engineered to optimize media temperature and maintain process integrity. A jacketed body allows heating or cooling fluids to circulate around the valve, preventing media solidification or crystallization. The blowout proof stem and ISO 5211 mounting pad add safety and automation readiness, while the anti-corrosion body coat and polished finish enhance lifespan, even in corrosive environments.

Versatile Operation and Broad Compatibility

Lever-operated for straightforward control, the valve suits manual applications across varying pressures (PN16 to PN40). Its adaptable design accommodates flanged, butt weld, and ANSI/DIN/JIS standard connections, covering port sizes 1/2" to 12". Whether handling gas, oil, or aggressive chemicals, it reliably manages multiple flow directions with L or T port options.

FAQ's of Jacketed 3 Way Ball Valve:

Q: How does the jacketed design benefit process operations?

A: The jacketed design allows heating or cooling media to flow around the valve body, maintaining optimal product temperature and preventing solidification or crystallization of the process media. This is especially beneficial for industries like chemical or food processing where consistent media temperature is critical.Q: What types of end connections are available for this valve?

A: Our jacketed 3 way ball valve comes with versatile end connections such as flanged and butt weld, compatible with ANSI, DIN, and JIS standards. This ensures easy installation and integration into various pipeline systems.Q: Where can this valve be installed for best performance?

A: This valve is ideally installed in applications requiring temperature-sensitive fluid handling, such as chemical, petrochemical, food, or pharmaceutical plants. It is suitable for systems dealing with water, oil, gas, steam, and aggressive industrial chemicals within -20C to 180C.Q: What is the process for selecting the correct seat material?

A: Seat material selection depends on the type of media, operating temperature, and pressure. PTFE offers good chemical resistance, CFT is suitable for higher pressures, and PEEK excels in elevated temperatures and aggressive media. Consulting with our engineering team ensures optimal seat choice for your application.Q: When should periodic maintenance be performed on this valve?

A: Regular maintenance depends on service conditions and media handled, but it's generally advised to inspect and service the valve at defined intervals as per your plant's maintenance schedule, especially when operating with viscous or corrosive fluids.Q: What is the main advantage of the L and T port flow patterns?

A: L and T port configurations allow flexible flow diversion or mixing. An L port is typically used for diverting flow between two outputs, whereas a T port enables mixing or distributing fluids to multiple flow paths, enhancing system versatility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

Mounting Pad Ball Valves

Material : Other, Stainless Steel / Carbon Steel / Cast Iron

Finish : Polished / Coated

Pressure : Other, PN16, PN25, Class 150, Class 300

Media : Other, Water, Oil, Gas, Steam, Chemical fluids

Structure : Other, Two Piece / Three Piece

Forged Steel High Pressure Ball Valve

Material : Other, Forged Steel

Finish : AntiCorrosion Coated

Pressure : Other, Up to 6000 PSI (420 bar)

Media : Other, Water, Oil, Gas, Steam

Structure : Other, Ball Valve

Fire Safe Ball Valve

Material : Other, Stainless Steel / Carbon Steel

Finish : Polished / Coated

Pressure : Other, Class 150 to Class 800

Media : Other, Water, Oil, Gas, Chemical

Structure : Other, Ball Valve

3 Way Gear Operated Ball Valve

Material : Other, Stainless Steel / Carbon Steel / Alloy Steel

Finish : Shot Blasted, Painted, or As Required

Pressure : Other, 150# / 300# / 600#

Media : Other, Water, Gas, Oil, Steam, Chemicals

Structure : Other, 3 Way Ball Valve

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry