Y Type Strainers

Product Details:

Y Type Strainers Price And Quantity

- 1 Set

Y Type Strainers Trade Information

- 1000 Set Per Day

- 1 Days

- Yes

- Free samples are available

- All India

Product Description

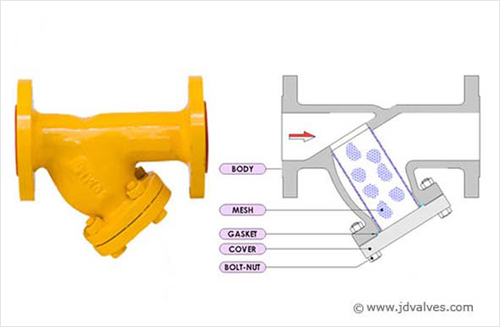

Our vision to excel and establish a strong foothold in the market has assisted us to evolve as a prominent manufacturer and exporter of Y Type Strainers. To manufacture these strainers we use optimum quality cast iron and mild steel. Strainers are mainly utilized for the evacuation of outside bodies in pipe line. Y Type Strainers are highly demanded in chemical, cement, petrochemical and oil refinery. We offer these strainers at cost effective prices.

Features:

- Robust construction

- Can withstand high pressure

- Corrosion proof

Further Details:

Y type strainers are titled after their shape as well as typically utilized for course straining. In any case, with substantial filtration range can be utilized with fine mesh as well. Structure of Y strainer is typically of cast steel or cast iron in different standards with socket and flanged weld sort end joint. Forged Y strainers are additionally accessible.

These Y type strainers have low weight drop because of higher stream area by screen. Y Strainer utilized for the evacuation of outside bodies in pipe line. These utilize line inconvenience free service as well as release expensive replacement or repairs for expansive area stressing punctured screen fixed with mesh of wire can be utilized. The Y type strainers enhance the discharge in the media, and extends the valves service life; ensure costly meter, pumps and different types of equipment. These are reasonable for water, gas, steam, sir, petroleum and different liquids.

Our strainers are obtainable in broad compatibility of pressure ranges, screen sizes and body material for different reasonable use. Y Type Strainers have the benefit of having the capacity to be installed in either vertical or horizontal position. But, in both instances, the screening component should be on the drawback of strainer body in order to captured strong particles can be legitimately gathered.

Our company can also provide rubber lines, fabricates, PTFE lined and jacketed strainers on demand of the customers.

A blow down fitting on the discharge port will permit wipe out without expulsion of the screen as well as without intruding on the procedure stream, offering on demand.

Design & Testing International Standard:

| Design Standard | Mfg. Standard |

| Pressure Testing | Mfg. Standard |

| Face To Face | ND 40 |

| Flange Drilling | ANSI B 16.5 / BS 10 Table / DIN / IS 6392 |

| Butt Weld End | ANSI B 16.25 |

| Socket Weld End | ANSI B 16.11 |

| Screwed End | ANSI B 1.20.1(BSP/NPT) |

| Pressure Rating | 125#, 150# |

| Size Range | 15mm () To 300mm (12) |

Material of Construction:

| Cast Iron | IS 210 Gr FG 200 |

| Cast Carbon Steel | ASTM A 216 Gr WCB |

| Cast Stainless Steel | ASTM A 351 Gr CF 8/CF 8M |

| End Connection | Screwed AS PER BSP/BSPT/NPT |

| Socketweld | AS PER ANSI B 16.11 |

| Flanged | AS PER ANSI B 16.5 (150#)/DIN 2545(PN 40) |

| Pressure Rating | ASA 125#, 150# |

| Size Range | 15 mm to 300 mm |

Material of Construction:

- Body & Cover

- Cast Iron to ASTM A 126 Class B

- IS 210 GR. FG 200 / 220 / 260

- Cast Carbon Steel to ASTM A 216 GR. WCB

- SS to ASTM A 351 GR. CF 8 / 8M / 3 / 3M

Others on request

- Mesh (Element)

- S.S. 304

- S.S. 316

- S.S. 304L

- S.S. 316L

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |