|

Fire Safe Ball Valves

Fire Safe Ball Valves Specification

- Caliber

- Standard/Full Bore

- Channels

- 2 Way

- Structure

- Two-piece / Three-piece

- Connection

- Flanged / Screwed / Welded

- Pressure

- Class 150/300/600/900

- Material

- Stainless Steel / Forged Steel / Carbon Steel

- Power

- Manual

- Media

- Water, Gas, Oil, Steam

- Temperature of Media

- -20C to 200C

- Port Size

- 1/2 to 12 (DN15 to DN300)

- Flange

- ANSI, DIN, JIS Standard

- Finish

- Polished / Painted

- Application

- Industrial, Chemical, Petroleum, Gas Plant, Power Plant

- Anti-static Device

- Provided

- Mounting Pad

- ISO 5211

- Sealing Type

- PTFE / Graphite Packing

- Testing Standard

- API 598 / EN 12266

- Blowout Proof Stem

- Yes

- Working Pressure

- Up to 40 Bar

- Design Standard

- API 607 / ISO 10497

- Leakage Class

- Class VI

- Fire Safe Certification

- Certified as per international fire safe standards

- End Connection

- Flanged, Threaded, Welded

- Body Material Grade

- CF8, CF8M, WCB

- Operation

- Lever / Gear

About Fire Safe Ball Valves

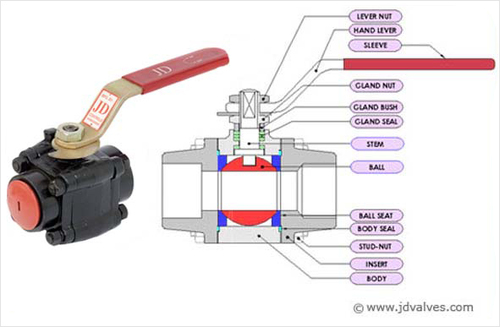

Fire Safe Ball Valves

Buy from us industrial grade Fire Safe Ball Valves that are designed and developed as per the production standards that make them structurally uniform and stable with an excellent resistance to extreme temperatures, pressure and flames that makes it suitable for harsh industrial conditions. These manually controlled fluid flow control device is also provided with flanged ends that makes it very easier to easily install the offered Fire Safe Ball Valves with the medium to high pressure pipelines.

Engineered for Superior Safety in Extreme Conditions

With internationally certified fire-safe design and robust body materials like CF8, CF8M, and WCB, these ball valves deliver reliable protection against fire hazards. Blowout-proof stems and anti-static devices further reinforce safety, making them a trusted choice for oil, gas, power, and chemical plants. The valves perform effectively in aggressive environments, handling media from water and oil to steam and gas.

Versatile Connection and Mounting Options

These valves offer standardized end connectionsflanged, threaded, and weldedcompatible with ANSI, DIN, and JIS norms. The ISO 5211 mounting pad simplifies actuator or gear installation. Users can select between polished or painted finishes to suit operation environments. Their adaptability from 1/2 to 12 (DN15 to DN300) and availability in two-piece or three-piece structures support both retrofits and new installations.

FAQs of Fire Safe Ball Valves:

Q: How are these fire safe ball valves tested and certified for fire safety?

A: The ball valves are rigorously tested according to API 607 and ISO 10497 standards to ensure fire resistance and safety integrity. Certification is provided following successful compliance with international fire-safe criteria.Q: What industries typically utilize these fire safe ball valves?

A: Industries such as chemical, petroleum, gas processing, power generation, and general industrial sectors deploy these valves due to their high reliability, safety features, and capability to operate across a broad pressure and temperature range.Q: When should PTFE or graphite packing be selected for the valve sealing?

A: PTFE packing is suitable for standard media and moderate conditions, while graphite packing should be chosen for applications involving higher temperatures or where enhanced fire and chemical resistance is required.Q: Where can these valves be installed in a piping system?

A: Engineered with versatile end connections (flanged, threaded, or welded), these valves can be installed at key control points in pipeline assemblies, whether for new installations or system upgrades across various industrial plants.Q: What is the process for operating these valves?

A: Operation is manual, using either a lever or gear mechanism, providing easy and secure on-off control of flow with minimal effort. The anti-static device ensures safe handling during operation, especially in flammable environments.Q: What benefits do the blowout-proof stem and anti-static device offer?

A: A blowout-proof stem maintains the integrity of the valve under high pressure, reducing the risk of accidents. The anti-static device prevents static discharge, making the valve safer for use with flammable gases and fluids.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

Pneumatic Ball Valve

Minimum Order Quantity : 1 Set

Media : Other, Water, Air, Oil, Gas

Finish : Polished

Material : Stainless Steel

Pressure : Other, PN16 / PN25 / 150PSI

Application : Industrial, Chemical, Water Treatment, Oil & Gas

Forged Steel High Pressure Ball Valve

Media : Other, Water, Oil, Gas, Steam

Finish : AntiCorrosion Coated

Material : Other, Forged Steel

Pressure : Other, Up to 6000 PSI (420 bar)

Application : Industrial, Petrochemical, Power Plants, High Pressure Systems

Fire Safe Ball Valve

Media : Other, Water, Oil, Gas, Chemical

Finish : Polished / Coated

Material : Other, Stainless Steel / Carbon Steel

Pressure : Other, Class 150 to Class 800

Application : Fire Safe Applications, Industrial, Petrochemical

Automation Series Ball Valve

Minimum Order Quantity : 1 Piece

Media : Water

Finish : Polished

Material : Stainless Steel

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry