|

Slurry Valves

Slurry Valves Specification

- Structure

- Gate

- Material

- Stainless Steel

- Power

- Manual

- Pressure

- High Pressure

- Media

- Slurry

- Working Temperature

- -20C to 200C

- Port Size

- 2 Inch

- Surface

- Polished

- Shape

- Round

- Application

- Used for controlling the flow of slurry in pipelines

- Flow Control

- Bi-directional

- End Connection

- Flanged

- Operation Type

- Handwheel

- Leakage Class

- Class VI

- Sealing Type

- Metal Seated

- Body Material

- SS 304/316

- Standard

- ANSI/API

- Corrosion Resistance

- Yes

- Seat Material

- Hard-faced Alloy

Slurry Valves Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Day

- Delivery Time

- 1 Days

About Slurry Valves

Under the exemplary leadership and guidance of our expert professionals, we have been able to emerge as a trusted manufacturer and supplier of Slurry Valves. We manufacture these valves using best quality cast iron and aluminum. Reinforced seats guarantee shape and position in the bore during operation improving the stability and performance. These valves are used in cement, mining and construction projects. Slurry Valves are used to handle tough and abrasive shut off applications involving slurries, powders or granular substances. We offer these valves at reasonable prices.

Features:

- Robust construction

- Easy to install

- Resistant to high pressure

Further Details:

Cast Iron and aluminum body, Slurry Valves possessing Rubber sleeves are additional hefty with complete covering spines anticipating erosion on body as well as four fortified pulling lugs for affirmative working. The sleeve is inside totally strengthened, therefore, our valves are having unique bolt nut instrument on wheel for premium fixing in shut position, limiting additional perpetual weight on sleeve, developing the life transverse of sleeve. Bolt nut provides sleeve fixing setting.

The sleeve is inside totally strengthened, which tolerate constant working. It is additionally planned, which will hold intact roundness in complete vacant location providing total circulation of pipe line.

Valves are glandless and fullway-seatless, Hefty Duty expendable Elastomere sleeve. Four strengthened pulling lugs offer definite and positive outcomes in closed and open position, averts sleeves from crumple even in void complete secured flanges shields from rust impacts. Our slurry valves can be penetrated to BS 10, IS, DIN or any standard.

Our valves consolidates all the altered outlines grounded on our incomprehensible experience in the domain. Valves are of finished solid development to manage different corrosive and abrasive fluids.

Characteristics:

- Straight Full Circulation. No Fluid Pounding

- Can Tolerate 8 Kg/Sq Cm Operating Pressure

- Utility In Void Upto Direct Pressure

- Impeccable Fixing Even On Entangled Solids

- Can Deal With Most Abrasive And Corrosive Materials

- Integrated Flange Gaskets

- Just Expendable Components- Elastic Sleeve !!

- Broke Casting Guarantee Fast Handling

- Hefty Duty Aluminum Alloy And Graded Cast Iron

SLEEVE AVAILABLE IN: L Neprene, Natural, Butyl, Hypalon, Viton. E.P.D.M. Or Special Suit Services.

Face to face Lengths: As per conventional Diaphragm Valves.

Materials to Handle :

- Chemicals, Alkaline Mixtures

- Viscous Fluids

- Sludges

- Gramles

- Acids, Slurries & Intermediates

- Liquid Foods

- Dry Suspension

- Powder Collectors

- Gases

Application Industries :

- Vacuum Sewage Plants

- Thermal P0wer Stations

- Water containing ash

- Pharmaceuticals

- Textile Industry

- Mining & Cement Industry

- Acid & Chemicals Tankers

- Refineries

- Fertilizers

| Size in mm | 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| L | 133 | 152 | 197 | 222 | 265 | 311 | 362 | 412 | 527 | 640 | 760 |

| H Open | 176 | 216 | 246 | 279 | 323 | 379 | 460 | 508 | 612 | 733 | 860 |

| D Dia | 120 | 140 | 165 | 185 | 203 | 229 | 279 | 305 | 368 | 432 | 480 |

Superior Engineering for Slurry Applications

Designed specifically for managing slurry flow in demanding environments, these valves combine a robust stainless steel body with a hard-faced alloy seat, ensuring both corrosion and abrasion resistance. Their flanged connections and round gate structure offer a secure fit in pipeline systems. Compliance with ANSI/API standards guarantees performance and reliability in high-pressure, industrial settings across India.

Precision and Bi-directional Flow Control

The handwheel-operated mechanism allows users to fine-tune flow, making these valves suitable for a range of operational needs. The bi-directional design ensures that flow can be precisely controlled regardless of the direction, minimizing leakage with a Class VI rating. This provides peace of mind and operational versatility for industries handling various slurry media.

FAQs of Slurry Valves:

Q: How does the metal-seated, hard-faced alloy design benefit slurry valve performance?

A: The metal-seated, hard-faced alloy construction provides outstanding resistance to abrasion and erosion caused by slurry media. This prolongs the valves service life, maintains reliable sealing under high-pressure conditions, and reduces maintenance frequency.Q: What applications are these slurry valves best suited for?

A: These valves are ideal for controlling the flow of abrasive or corrosive slurries in industrial pipelines, commonly used in mining, chemical processing, and wastewater treatment where durability and leak-tight operation are critical.Q: When should I choose a bi-directional slurry valve?

A: A bi-directional valve should be selected when the slurry flow direction may change within the pipeline. This feature allows the same valve to reliably seal and control flow in either direction, increasing system flexibility and minimizing the need for multiple valves.Q: Where are these slurry valves manufactured and supplied from?

A: These valves are manufactured, supplied, and exported from India, ensuring adherence to global ANSI/API standards and providing reliable solutions to international and domestic markets.Q: What is the process for manually operating these valves?

A: Operation is performed using the handwheel, which opens or closes the valve gate, allowing precise adjustment of slurry flow. Manual actuation is advantageous in environments requiring hands-on control and robustness over automated alternatives.Q: Which features enhance the corrosion resistance of the valve?

A: The use of SS 304/316 stainless steel for the body and hard-faced alloy for the seat endows the valve with high resistance against corrosive substances commonly found in slurry, extending operational longevity even in aggressive environments.Q: What are the primary benefits of using a Class VI leakage valve for slurry media?

A: A Class VI leakage rating ensures extremely tight shutoff, significantly reducing the risk of leakages even under high-pressure and high-wear conditions. This is essential for maintaining safety, environmental compliance, and process efficiency in slurry handling applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Valve Category

Swing Check Valves

Minimum Order Quantity : 1 Set

Port Size : 2 to 24 (Inches)

Surface : Other, Red Epoxy Coated

Application : Water Supply, Industrial, HVAC

Power : Manual

Pressure : High Pressure Bar

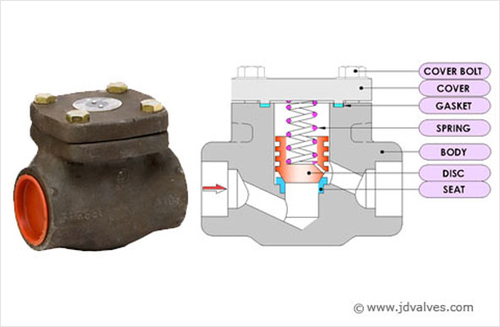

Forged Steel Check Valve

Minimum Order Quantity : 500 Sets

Port Size : 1/2 inch to 2 inches

Surface : Other, Anticorrosive Coated

Application : Oil, Gas, Petrochemical Industries

Power : Manual

Pressure : Other, Up to 800 lbs

Industrial Control Valve

Minimum Order Quantity : 1 Set

Port Size : 1/2 inch to 8 inch

Surface : Other, Polished

Application : Industrial Automation, Fluid Handling, Process Control

Power : Pneumatic

Pressure : Other, 10 Bar

Diaphragm Valves

Minimum Order Quantity : 1 Set

Port Size : 15mm to 300mm

Surface : Other, Epoxy Painted, Polished

Application : Industrial, Water Treatment, Chemical Processing

Power : Manual

Pressure : Medium Pressure

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry