|

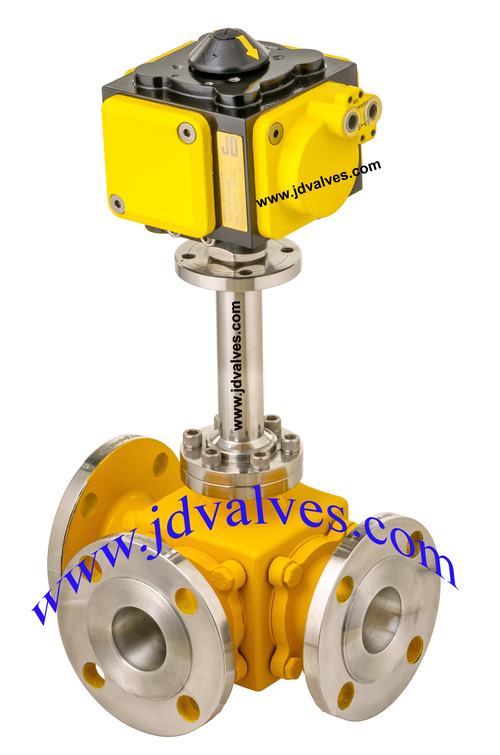

4 Way Ball Valves

4 Way Ball Valves Specification

- Connection

- Flanged, Threaded

- Pressure

- 1.0 MPa to 6.4 MPa (PN10PN64)

- Structure

- 4 Way Ball Valve

- Channels

- Four Way

- Caliber

- DN15 to DN150

- Material

- Stainless Steel, Carbon Steel, Brass

- Power

- Manual, Pneumatic, Electric

- Media

- Water, Oil, Gas, Steam, Chemical Fluids

- Port Size

- 1/2 to 6

- Flange

- ANSI, DIN, JIS Standards

- Finish

- Polished, Electroplated

- Application

- Process Industries, Chemical Plants, Water Treatment, Oil & Gas

- Sealing Type

- PTFE, Metal to Metal

- Number of Seats

- 2 or 4 Seat Design

- Flow Pattern

- L Port or T Port

- Blow-Out Proof Stem

- Yes

- Operation Type

- Quarter Turn

- Body Coating

- Epoxy Painted, Nickel Plated

- Fire Safe Design

- Available

- Anti-Static Device

- Yes

- End Connection Type

- Screwed, Socket Weld, Butt Weld

- Handle Type

- Lever or Gear Operated

- Test Standard

- API 598, EN 12266

- Leakage Class

- Class VI / Bubble Tight

- Mounting Pad

- ISO 5211

About 4 Way Ball Valves

4 Way Ball Valves

We have built our reputation in manufacturing, exporting and supplying a quality 4 Way Ball Valves. This ball valve is manufactured using supreme quality materials sourced from the trusted merchants of the industry. Due to features like rugged construction, high operational fluency and low maintenance, this 4 Way Ball Valves is highly appreciated in national & international market. Further, this ball valve is tested as per the predefined industry parameters. The ball valve is available at cost effective price.

We have an extensive variety of Four Way and Three Way Ball Valve in Stainless steel, Carbon Steel, Cast Iron and various others metal on particular demand of the customers. Our four way and Three Way Ball Valve determination covers regular (reduce port) and Full Port, screwed end, butt solder (soldered neck) end, flanged end, socket weld as well as tri-clover end along with pneumatic, hand operated hand lever or gear.

Salient Features:

- Compact Design

- High Performance Ball Valve

- Low Pressure Drop

- Longer Life

- Simplicity

- Positive Shut off

- No Lubrication

- Quick in Action

Design & Testing International Standard:

Valve Design: BS 5351 / ANSI B 16.34 / API 6D

Pressure Testing: BS 6755 Part II / API 598 / API 6D

Face To Face: Mfg. Standard

Flange Drilling: ANSI B 16.5 / BS 10 Table / DIN / IS 6392

Butt Weld End: ANSI B 16.25

Socket Weld End: ANSI B 16.11

Screwed End: ANSI B 1.20.1(BSP/NPT)

Material of Construction:

Body / End Connector Piece:

Cast Iron to ASTM A 126 Class B IS 210 GR. FG 200 / 220 / 260

Ductile Iron to ASTM A 536 Grade 65-45-12

Cast Carbon Steel to ASTM A 216 GR. WCB

Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M

Hast Alloy B / C

ASTM A 351 GR. CN 7M (Alloy 20)

Ball:

Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M

Hast Alloy B / C

ASTM A 351 GR. CN 7M (Alloy 20)

Stem:

AISI 410 (S.S. 410 13% Cr. Steel)

AISI 304 (S.S. 304)

AISI 316 (S.S. 316)

AISI 304L (S.S. 304L)

AISI 316L (S.S. 316L)

Hast Alloy B / C

Alloy 20

Ball Seat / Gland Seal / Stem Seal:

Grafoil

P.T.F.E. Virgin

P.T.F.E. Glass Filled

P.T.F.E. Carbon Filled

TECHNICAL SPECIFICATIONS:

| Size | Rating | Class 150 | ||||||

| Inch | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | |

| DN | 25 | 40 | 50 | 65 | 80 | 100 | 150 | |

| L-Full Bore | 165 | 215 | 245 | 295 | 325 | 380 | 450 | |

| L-Reduce Bore | - | - | - | 245 | 295 | 325 | 380 | |

| G-Full Bore | 25 | 38 | 50 | 63 | 75 | 100 | 150 | |

| G Reduce Bore | - | - | - | 50 | 63 | 75 | 100 | |

| H-Reduce Bore | - | - | - | 63 | 75 | 100 | 150 | |

| D | 108 | 127 | 152.4 | 177.8 | 190.5 | 228.6 | 279 | |

| E | 79.3 | 98.4 | 120.6 | 139.7 | 152.4 | 190.5 | 240.3 | |

| F | 50.8 | 73 | 92.1 | 104.7 | 127 | 157.2 | 215.9 | |

| N | 4 | 4 | 4 | 4 | 4 | 8 | 8 | |

| O | 15.8 | 15.8 | 19 | 19 | 19 | 19 | 22.2 | |

| Size | Rating | Class 300 | ||||||

| Inch | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | |

| DN | 25 | 40 | 50 | 65 | 80 | 100 | 150 | |

| L-Full Bore | 178 | 220 | 260 | 311 | 344 | 400 | 473 | |

| L-Reduce Bore | - | 178 | 220 | 260 | 311 | 344 | 400 | |

| G-Full Bore | 25 | 38 | 50 | 63 | 75 | 100 | 150 | |

| G Reduce Bore | - | 25 | 38 | 50 | 63 | 75 | 100 | |

| H-Reduce Bore | - | 38 | 50 | 63 | 75 | 100 | 150 | |

| D | 124 | 155.4 | 165.1 | 190.5 | 209.5 | 254 | 317.5 | |

| E | 88.9 | 114.3 | 127 | 149.3 | 168.1 | 200.1 | 269.7 | |

| F | 50.8 | 73 | 92.1 | 104.7 | 127 | 157.2 | 215.9 | |

| N | 4 | 4 | 8 | 8 | 8 | 8 | 12 | |

| O | 19 | 22 | 19 | 22 | 22 | 22 | 22 | |

Precision Flow Control for Complex Systems

Our 4 Way Ball Valves allow users to manage multiple flow channels with ease, thanks to robust quarter-turn operation and selectable L or T port configurations. These valves ensure precise media control and are tailored to meet a variety of industrial process requirements. The availability of 2 or 4 seat designs provides flexibility for diverse operational setups.

Multiple Connection and Mounting Options

Offered with ISO 5211 mounting pads and a choice of end connectionsscrewed, socket weld, butt weld, or flanged (ANSI, DIN, JIS)these valves integrate seamlessly into existing systems. Our valves support easy installation and maintenance, optimizing reliability in your process line.

Engineered for Safety and Longevity

Featuring fire-safe construction, anti-static devices, and blow-out proof stems, safety is paramount in our 4 Way Ball Valve design. Epoxy-coated or nickel-plated body ensures durability, while a range of power optionsmanual, pneumatic, or electriccaters to all operational needs.

FAQs of 4 Way Ball Valves:

Q: How does the four-way ball valves flow pattern (L Port or T Port) affect its application?

A: The choice between L Port and T Port flow patterns determines how liquids or gases are routed through the valve. L Port directs flow between three of the four ports, making it ideal for diverting applications. T Port enables complex mixing or distribution tasks, beneficial in process industries requiring flexible routing or blending.Q: What sealing types are available for the 4 Way Ball Valve and when should each be used?

A: Our valves are offered with PTFE and Metal-to-Metal sealing. PTFE provides superior chemical resistance and is preferable for most water, steam, or chemical applications. Metal-to-Metal is suited for high-temperature or abrasive media, often required in oil & gas or heavy-duty chemical plants.Q: Where can these valves be installed, considering mounting and end connection options?

A: These 4 Way Ball Valves feature ISO 5211 mounting pads for direct actuator installation and offer a variety of end connections including screwed, socket weld, butt weld, and flanged per ANSI, DIN, or JIS standards. They are suitable for integration in any process system, including piping arrangements in chemical, oil refinery, or water treatment facilities.Q: What is the process for ensuring leak-tight performance in these ball valves?

A: Each valve is tested in accordance with API 598 and EN 12266 standards, guaranteeing a Class VI (bubble tight) leakage rate. Regular maintenance and correct seal selection further preserve leak-free operation over the valves lifecycle.Q: How do the fire safe design and anti-static device benefit valve usage in process industries?

A: The fire safe design provides protection during thermal incidents, limiting the risk of leaks in hazardous environments. The anti-static device prevents sparking caused by the build-up of static electricity, ensuring safer operation, especially for flammable media such as oil or gas.Q: What are the advantages of the available handle types for valve operation?

A: Valves can be operated with either lever or gear handles. Lever operation is best for fast, straightforward actuation in smaller sizes, while gear operation provides greater torque for larger valves or higher-pressure systems, allowing precise control with less manual effort.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

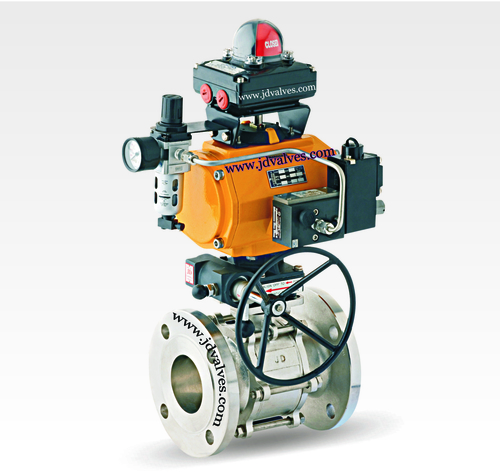

Three Way Ball Valves

Minimum Order Quantity : 1 Set

Finish : Polished / Painted / Powder Coated

Material : Other, Stainless Steel / Cast Steel / Carbon Steel / Brass / PVC

Media : Other, Water, Gas, Oil, Steam, Acid, Alkali

Pressure : Other, PN16, PN25, PN40 or Class 150/300 (as per model)

Structure : Other, Three Way

Fire Safe Ball Valves

Finish : Polished / Painted

Material : Other, Stainless Steel / Forged Steel / Carbon Steel

Media : Other, Water, Gas, Oil, Steam

Pressure : Other, Class 150/300/600/900

Structure : Other, Twopiece / Threepiece

Jacketed Ball Valves

Finish : Polished or Painted

Material : Other, Stainless Steel, Carbon Steel, Alloy Steel

Media : Other, Steam, Oil, Chemical, Water, Gas

Pressure : Other, Class 150 to 900

3 Piece Ball Valves

Minimum Order Quantity : 10 Pieces

Finish : Polished

Material : Stainless Steel

Pressure : High Pressure

Structure : Control

|

J. D. CONTROLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry